Difference between PDC and PCD

Difference between PDC and PCD

PDC and PCD are both super hard new materials. What’s the difference between them?

PCD (Polycrystalline Diamond) is made from diamond grit. The diamond grit has been fused under high-pressure, high-temperature conditions in the presence of a catalytic metal. PCD has an extreme hardness, wear resistance, and thermal conductivity to diamond, which makes PCD an ideal material for cutting tools manufacturing. PCD tools ( like PCD insert and PCD blades) can machine all non-ferrous materials such as those used in the woodworking industry, chipboards, HDF, and laminated boards. PCD is being used in the automotive industry to produce aluminum components and all lightweight materials such as carbon fiber reinforced plastics (CFRP), metal matrix composites (MMC), and stacks for aircraft construction.

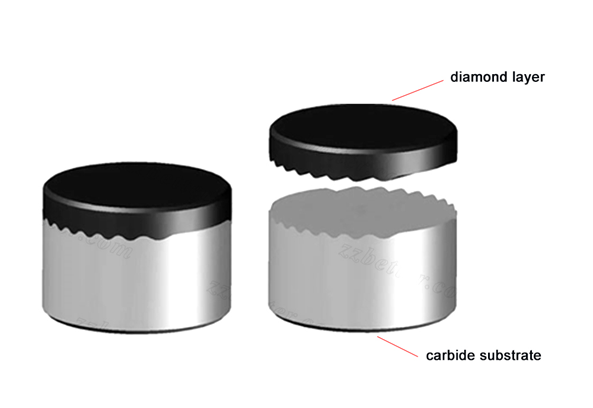

PDC (Polycrystalline Diamond Compact) refers to polycrystalline diamond composite or compact, which is the most rigid tool material among all diamond tool materials. It is made by combining some layers of polycrystalline diamonds (PCD) with a layer of cemented carbide substrate at high temperature and high pressure. The temperature is around 1400~1700℃, and the pressure is around 6-7 GPA. A cobalt alloy is also present and acts as a catalyst for the sintering process. The cobalt helps bond the carbide and diamond. PDC has the advantages of diamond’s high wear resistance with carbide’s good toughness.

The Main Advantages of PDC

High wear resistance

High impact resistance

High thermal stability

The working life of the PDC cutters is increased by more than 6~10 times

Reduce the frequency of replacement of drilling bits and the labor intensity of workers.

Due to their high performance, the PDC cutters are widely used in the below aspects:

Oil and gas PDC bits as the face, gauge, and backup cutters

PDC bits for geothermal drilling

PDC bits for water well drilling

PDC bits for directional drilling

Here at zzbetter, We supply a wide shape and size range of PDC cutters.

The shape of zzbetter PDC Cutter

1. Flat PDC cutter

2. Spherical PDC button

3. Parabolic PDC button, front button

4. Conical PDC button

5. Square PDC cutters

6. Irregular PDC cutters

If you are interested in PDC cutters and want more information and details, you can CONTACT US by phone or mail at the left, or SEND US MAIL at the bottom of the page.