How to Improve the Wear Resistance of Carbide Wear Parts?

How to Improve the Wear Resistance of Carbide Wear Parts?

The wear performance of the tungsten carbide is affected by the use of the environment and alloy performance. The wear resistance is mainly determined by the microstructure and chemical composition. The main structural parameters of the cemented carbide are the grain size and bonding phase content. The wear resistance is also affected by the added elements such as barium.

In industrial production, much important mechanical equipment and their mechanical parts are in harsh conditions, such as high speed, high temperature, high pressure, over-serving, etc. Therefore, the damages to mechanical components occur frequently due to wear, corrosion, and oxidation, which are mostly caused by the surface.

The surface protective measures are used to delay and control the damage, which has become an effective method for solving the wear of mechanical parts. Therefore, various surface abrasion techniques for mechanical parts are adopted, such as plating, thermos, carburizing, nitriding, permeable metals, thermal spraying, surfacing, coating, and pasting the hardening layer, high energy beam, etc.

The rare earth has been successfully applied in the carbide wear part. When the strength and the impact toughness increase by more than 10%, the wear resistance of carbide wear parts also improves.

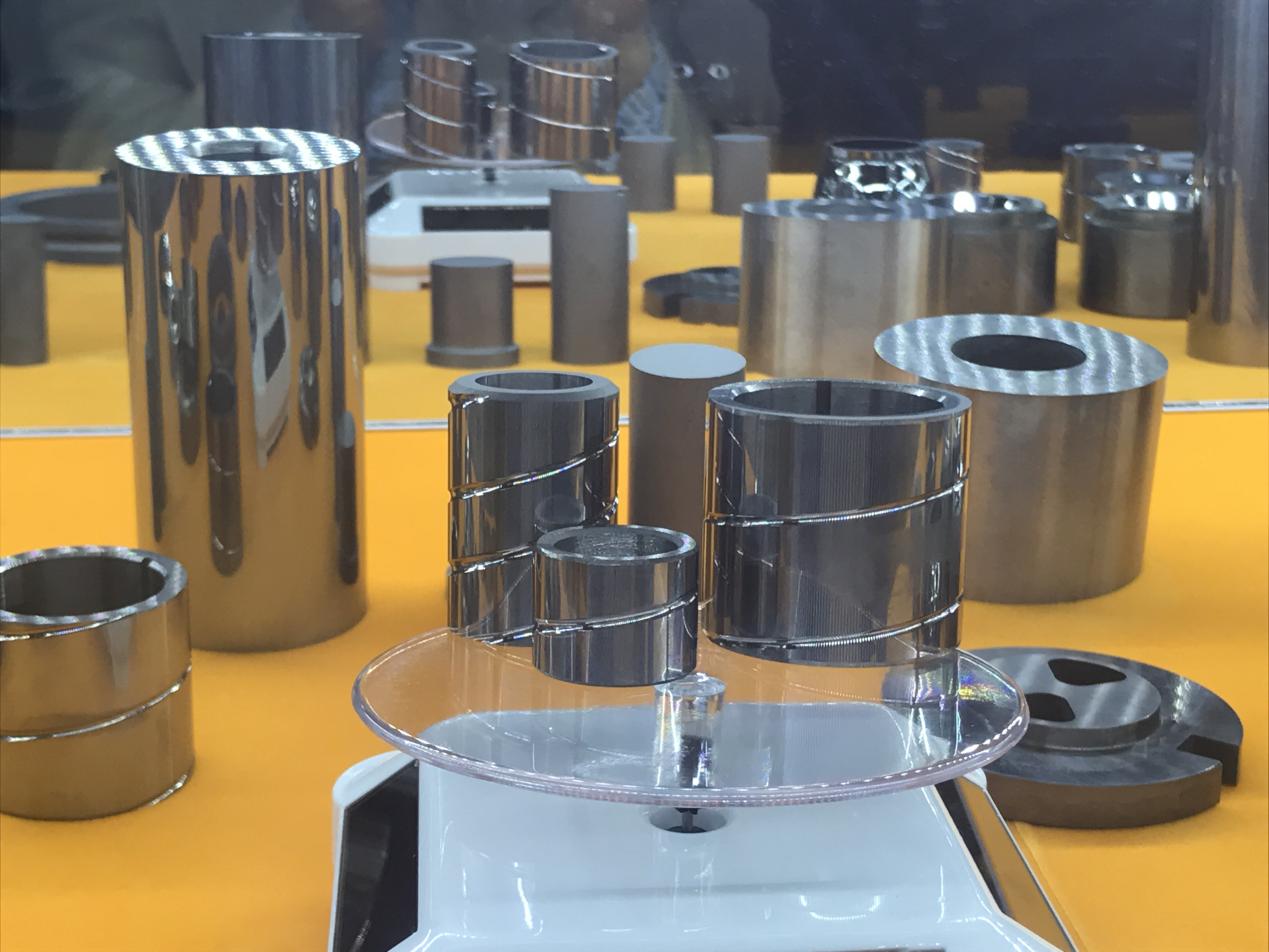

For example, Tungsten carbide mold parts have good performance and are widely used in the mold parts processing industry. In order to maximize its value, it is important to improve the wear resistance of tungsten carbide mold parts.

Generally speaking, the most effective and direct way to improve the wear resistance of tungsten carbide mold parts is titanium plating processing - surface life, hardening, value-added and wear resistance, corrosion resistance, etc.

The surface of the precision weighing die coated with vacuum coating can have a very low friction coefficient, which reduces the processing force. Cold stamping and drawing die coated with vacuum coating can significantly reduce friction, scratch, and wear during processing. Therefore, it can increase the life span and reduce the cost substantially.

Advantages:

1. Reduce friction coefficient, reduce processing force, improve surface hardness, and greatly prolong die life.

2. In using the die, the problem of early failure is often solved.

3. Make the best of the workpiece to play a full role.

4. Vigorously improve the quality (such as surface roughness, accuracy, etc.) and the service life of mold parts, so as to make them play the potential of products effectively.

If you are interested in tungsten carbide products and want more information and details, you can CONTACT US by phone or mail at the left, or SEND US MAIL at the bottom of the page.