The Application Of Tungsten Carbide

The application of tungsten carbide

Products made of tungsten carbide are preferred over other strong metals for their incredible hardness, extreme toughness, wear resistance, and great density. Tungsten carbide is the most common industrial use of tungsten in the world so far. It is quite suitable for making many kinds of machine tools, So tungsten carbide can be found in many filed of different applications. The most advanced and recent application field of tungsten carbide is the automotive, aerospace, medical field, jewelry, oil & mineral exploration together with the construction sector. There are some applications of tungsten carbide in detail are as followed.

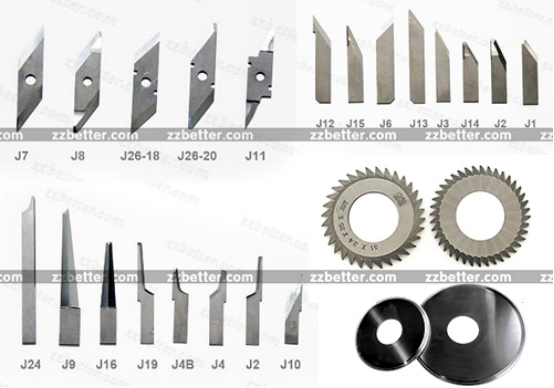

1. Cutters

Cemented carbide finds a large application in the cutter. As we all know a series of excellent advantages such as high hardness, wear-resistance, and toughness, heat resistance. Especially its hardness and heat resistance. Even at a high temperature of 500 degrees, remains unchanged, and still has a high hardness at 1000 degrees. Thus, it’s popular in the field of cutters. It is been used to cut cast iron, non-ferrous metals, plastics, graphite, glasses, chemical fibers, stainless steel, and some other difficult-to-process materials. Its cutting speed is hundreds of times higher than that of carbon steel. It is an excellent product to let the industry make more with less. Some commonly used cutter tools are turning tools, milling cutters, drilling cutters and etc.

2. Mining and drilling

Drilling and mining tools made from tungsten carbide can be used for various construction applications. Because of its better performance than steel tools, tungsten carbide drilling and milling tools have experienced rapid development. It has resulted in the increasing replacement of steel tools by tungsten carbide tools. More than half of the tungsten carbide goes into the market for the use of mining and drilling filed. Especially in the oil sector. While Carbide bits and tips last longer, they still need to be periodically replaced.

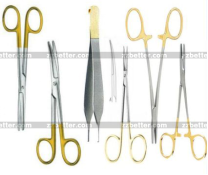

3. Medical tools

The use of tungsten carbide in the medical industry offers another important application for the material. Surgical tools are typically made of stainless steel or titanium, while the tip, blade, or end is made from tungsten carbide. On the one hand, tungsten carbide can help the tool have much greater longevity, on the other hand, tungsten carbide blades can be sharpened to have a much finer edge due to the material’s hardness.

The use of tungsten carbide in the medical industry offers another important application for the material. Surgical tools are typically made of stainless steel or titanium, while the tip, blade, or end is made from tungsten carbide. On the one hand, tungsten carbide can help the tool have much greater longevity, on the other hand, tungsten carbide blades can be sharpened to have a much finer edge due to the material’s hardness.

4. Wear Parts

Tungsten carbide is widely used in the industry for its superior performance. High- hardness and good wear resistance make it suitable for manufacturing wear-resistant parts, mechanical parts and wire drawing dies. That’s why in recent years, cemented carbide has become the best choice to replace steel in wear part applications. There are a huge amount of products that are made from tungsten carbide such as balls for ball-point pens to hot rolls for rolling mills.

5. Jewelry

The latest application of tungsten carbide is used for making jewelry. Because of its good performance in high hardness and resistance, it is an attractive material to use for making rings, pendants, earrings, and other jewelry. As long as it has been cut and polished correctly, the finished product can be beautiful and shining as well.

Tungsten can be used not only in the above fields but also in navigation, atomic energy, shipbuilding, automobile industry, and other fields. With the development of the downstream industry, the market demand for tungsten carbide is increasing. And in the future, the manufacture of high-tech weapons equipment, the progress of cutting-edge science & technology, and the rapid development of nuclear energy will greatly increase the demand for tungsten carbide products with high technology content and high-quality stability.