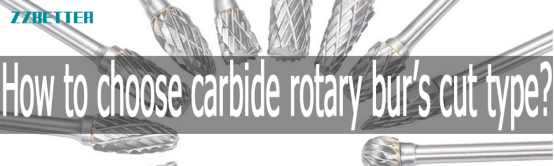

How To Choose Carbide Rotary Bur's Cut Type?

How to choose carbide rotary bur’s cut type?

Tungsten carbide rotary burrs are also called die grinder bits or cemented carbide burrs. They are wildly used in the dental field, industrial field, and beauty nail field. Carbide burrs are generally used for metalworking, wood carving, welding, casting, grinding, chamfering, and deburring. With so many applications, Do you know how to choose the right cut type? Pick the right one that can surpass your needs as much as possible.

1. Single-cut burr

The most commonly used tooth type of tungsten rotary carbide burrs are single-cut and double-cut, here I’d like to start with the single-cut which can also be called standard cut or single groove knife. It is more suitable for iron, steel, stainless steel, copper, brass, and other hard objects. The single-cut is not an ideal cut to use in soft objects due to the grain of the single groove. Because when it is working and cutting, the broken waste is easy to block the tool groove. The result is that the texture depth of the cut becomes shallow and causes the cutting ability to decrease. The single-cut is not quite suitable for beginners, because the single-cut burr causes many “burrs jumping”. Then you may wonder what is suitable for beginners? Don’t worry, I’ll tell you soon.

The most commonly used tooth type of tungsten rotary carbide burrs are single-cut and double-cut, here I’d like to start with the single-cut which can also be called standard cut or single groove knife. It is more suitable for iron, steel, stainless steel, copper, brass, and other hard objects. The single-cut is not an ideal cut to use in soft objects due to the grain of the single groove. Because when it is working and cutting, the broken waste is easy to block the tool groove. The result is that the texture depth of the cut becomes shallow and causes the cutting ability to decrease. The single-cut is not quite suitable for beginners, because the single-cut burr causes many “burrs jumping”. Then you may wonder what is suitable for beginners? Don’t worry, I’ll tell you soon.

2. Double-cut burr

Here is the answer, the double-cut burr also called double-slot burr, cross-cut or double grooves burrs, It is easy to control, handle, and an ideal tungsten carbide burr tool for beginners. Because the grain is crossed, the chip removal with a cross pattern is fast, and it is not easy to block the grain when cutting and polishing. Also, its working speed would be slower than normal speed. Tungsten carbide rotary burr with cross-cut is more appropriate to fit objects with a relatively low density such as wood, aluminum, plastic, and some soft objects.

Here is the answer, the double-cut burr also called double-slot burr, cross-cut or double grooves burrs, It is easy to control, handle, and an ideal tungsten carbide burr tool for beginners. Because the grain is crossed, the chip removal with a cross pattern is fast, and it is not easy to block the grain when cutting and polishing. Also, its working speed would be slower than normal speed. Tungsten carbide rotary burr with cross-cut is more appropriate to fit objects with a relatively low density such as wood, aluminum, plastic, and some soft objects.

3. Aluminum cut burr

Aluminum cut burrs are also called fast mill cut burrs. They are used for grinding and shaping aluminum and other nonferrous and nonmetallic metals. It is designed for rapid disassembly of inventory with minimum chip load. They are used in electric, pneumatic, and hydraulic mold grinders. Aluminum cut burrs are basically electric files that can be precisely focused and ground in small space, for a mechanic, businessman, and amateur use.

Aluminum cut burrs are also called fast mill cut burrs. They are used for grinding and shaping aluminum and other nonferrous and nonmetallic metals. It is designed for rapid disassembly of inventory with minimum chip load. They are used in electric, pneumatic, and hydraulic mold grinders. Aluminum cut burrs are basically electric files that can be precisely focused and ground in small space, for a mechanic, businessman, and amateur use.

4. Chip breaker cut burr

Chip breaker cut burr can reduce sliver size and improve operator control at a slightly reduced surface finish.

5. Coarse cut burr

Coarse cut burrs are recommended for use on soft materials such as copper, aluminum, plastics, brass, and rubber, where chip loading is a problem.

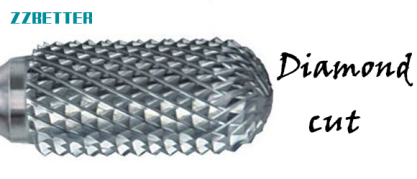

6. Diamond cut burr

Diamond cut burr is very effective in heat treatment and tough alloy steels. It produces extremely small chips. it is also a good type for beginners. Diamond cut rotary burrs offer good operator control, but the sacrifice is the surface finish and tool life reduction.

Above six cut types are the normal style of tungsten carbide rotary burrs. And if a special type of the burs you need is outside the normal offering, we are here to provide a dedicated engineering team with advanced equipment to create precise custom types for you.