Instructions Of Using Tungsten Carbide Rotary Burrs

Instructions of using tungsten carbide rotary burrs

The rotary file is clamped on a high-speed rotating tool for manual control, the pressure and feed speed of the rotary file are determined by the service life and cutting effect of the tool.

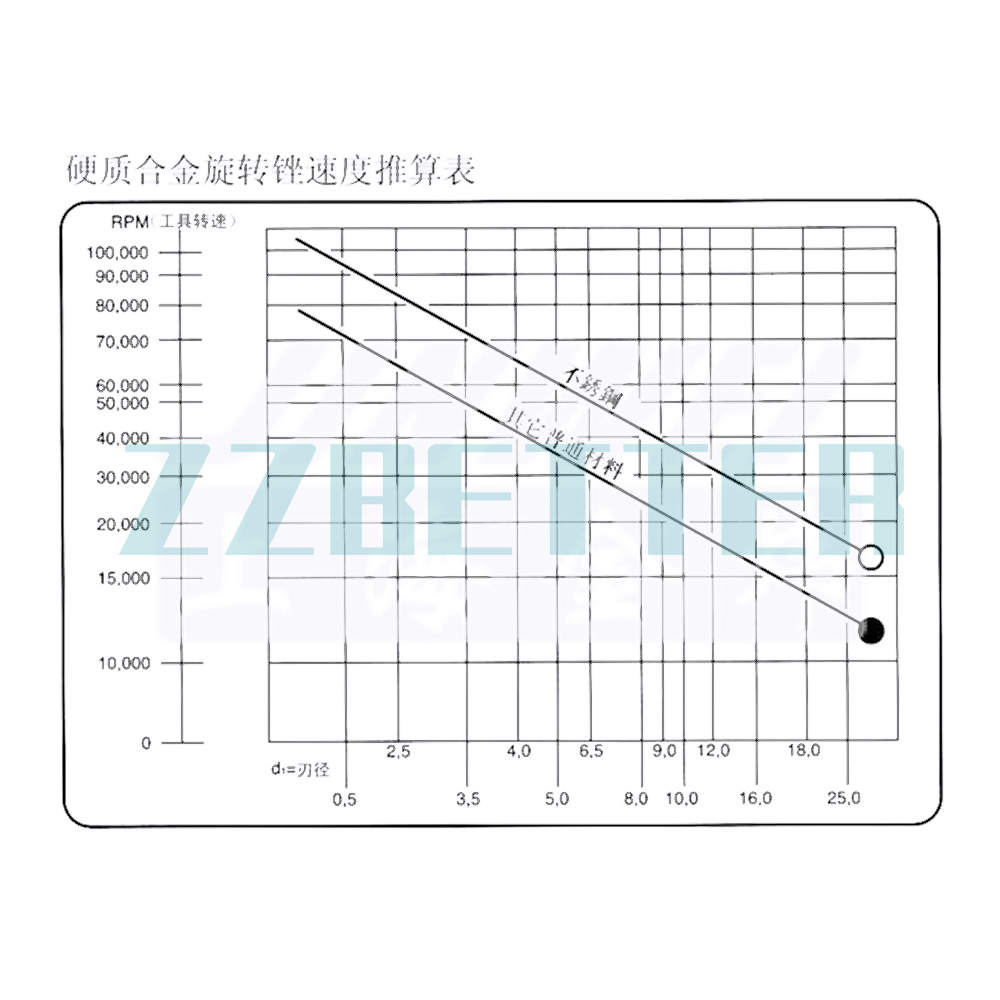

When the rotary file is used at a high speed, it will have a very high cutting effect, and it can also prolong the service life of the tool. While excessive force, excessive pressure, or low speed will affect the chip effect and reduce the service life of the tool (it is recommended to refer to the rotary file speed calculation table, the use pressure is in the range of 0.5-1kg).

Here are the tips:

1. Avoid increasing the pressure in the case of the low speed of the machine, which will make the edge of the rotary file hot, and it is easy to blunt the edge when used at high temperature, thus affecting the service life.

2. Make the blade of the rotary file touch the workpiece as much as possible, and the proper pressure and feed speed will make the blade go deep into the workpiece so that the machining effect will be better.

3. Avoid the welding part of the rotary file (the joint between the tool head and the handle) to contact the workpiece, so as to reduce the damage to the welding part caused by overheating.

4. Replace the blunt rotary file in time.

Note: the blunt rotary file when it’s working, would be slow to cut. Do not in order to increase the speed to increase the pressure, If so, it will increase the load of the machine and cause damage to the rotary file and the machine. It will cause much cost.

5. It can be used with cutting coolant during operation.

Note: machine tools can use flowing cooling liquid, While hand tools can use coolant liquid or coolant solid.