The Physical Property Of Tungsten Carbide

The physical property of tungsten carbide

Modern technology has a wide range of applicability for the unique alloy tungsten-cobalt. Why it is so popular? Here are some physical properties of tungsten carbide. After reading this passage you will know more detail about it.

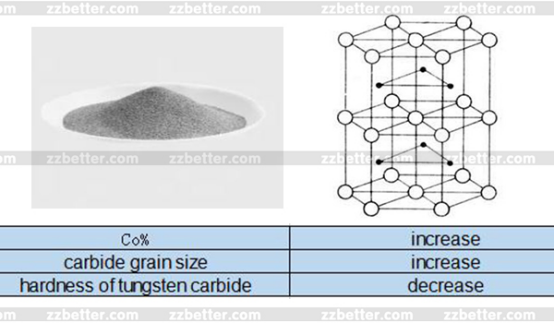

Hardness.

We all know that diamond is one of the hardest natural materials in the world. While the hardness of tungsten carbide is second to diamond. Hardness is one of the main mechanical properties of cemented carbide. With the increase of cobalt content in the alloy or the increase of carbide grain size, the hardness of the alloy decreases. For example, when the cobalt content of industrial WC-Co increases from 2% to 25%, the hardness of the alloy decreases from 93 to about 86. For every 3% increase of cobalt, the hardness of the alloy decreases by 1 degree. Refining the grain size of tungsten carbide can effectively improve the hardness of the alloy.

Bending strength.

Like hardness, bending strength is one of the main properties of cemented carbide. There are many complex factors affecting the bending strength of the alloy, Generally speaking, the bending strength of the alloy increases with the increase of cobalt content. However, when the cobalt content exceeds 25%, the bending strength decreases with the increase of cobalt content. As far as industrial WC-Co alloy is concerned, the bending strength of the alloy always increases with the increase of cobalt content in the range of 0-25%.

Compressive strength.

The compressive strength of cemented carbide indicates the ability to resist compression load. With the increase of cobalt content and increases with the grain size of the tungsten carbide phase in the alloy the compressive strength of WC-Co alloy decreases. Therefore, the fine-grain alloy with lower cobalt content has higher compressive strength.

Impact toughness.

Impact toughness is an important technical index of mining alloys, and it also has practical significance for intermittent cutting tools under harsh conditions. The impact toughness of WC-Co alloy increases with the increase of cobalt content and the grain size of tungsten carbide. Therefore, most of the mining alloys are coarse-grained alloys with high cobalt content.

Magnetic saturation.

The magnetic induction intensity of the alloy increases with the increase of the external magnetic field. when the magnetic field intensity reaches a certain value, the magnetic induction intensity no longer increases, that is, the alloy has reached magnetic saturation. The magnetic saturation value of the alloy is only related to the cobalt content in the alloy. Therefore, the magnetic saturation can be used to check the non-destructive composition of the alloy or to identify whether there is a non-magnetic η l phase in the alloy with known composition.

Elastic modulus.

Because WC has a high elastic modulus, so as WC-Co. The elastic modulus decreases with the increase of cobalt content in the alloy, and the grain size of tungsten carbide in the alloy has no obvious effect on the elastic modulus. With the increase of service temperature the elastic modulus of the alloy decreases.

Thermal expansion coefficient.

The linear expansion coefficient of WC-Co alloy increases with the increase of cobalt content. However, the expansion coefficient of the alloy is much lower than that of steel, which will cause greater welding pressure when the alloy tool is inlaid and welded. If slow cooling measures are not taken, the alloy will often crack.

All in all, Tungsten carbide has a high performance in its physical properties. Of cause, The relevant physical properties of cemented carbide are not limited to those. The characteristics of materials with different formulations for specific uses will also be different. Wanted to know more about tungsten carbide welcome to follow us.