Design and Application of Device of Rapidly Replacing Studs on Surface of HPGR Roller

Design and Application of Device of Rapidly Replacing Studs on Surface of HPGR Roller

Key Words: HPGR; surface of studded roller; device of replacing stud;force point;stress point;Brazing test;

To solve the difficulty in replacing studs on the surface of the HPGR roller, a device of rapidly replacing the studs was designed, and the method of replacing the studs was introduced. The device was characterized by simple operation, repeated utilization, short replacement duration, and long service life span. It could reduce the equipment maintenance and repair cost and time, and effectively protect the roller sleeve. Slowing down the wearing rate and prolonging the service lifespan.

Because the stud is installed in the stud hole utilizing a gap fit through the binder, the relatively soft stud sleeve will be deformed after extrusion after a period of use, and the broken nail exposed part of the roller sleeve is limited, and even some studs break inside the roller sleeve. Because there is no force to disassemble the broken stud, it is very difficult to replace the broken stud. Even if the bonding agent fails by heating, the stud is still difficult to pull out. Therefore, it is very important to develop a fast replacement device for roller face studs to prolong the life of the roller face.

The principles of replacing studs:

Stud and stud holes are intensified and fixed by adhesive. Since the adhesive will fail after heating to a certain temperature, the adhesive can be disabled by heating the stud and then the damaged stud is taken out by drawing. However, because the residual part of the stud is usually buried in the hole of the stud when it is broken, it is difficult to bear force, so it is necessary to weld the stress point on the residual studs by welding.

Welding test:

In the process of taking the broken nail, it is necessary to weld the stud and the nail-changing device together with a certain strength. Because the stud is cemented carbide, it is difficult to fuse with the welding material, so choosing the right welding method and welding material becomes the key to pulling the studs. To overcome the problem of welding stress in the process of stud replacement, welding tests of cemented carbide studs were carried out by arc welding and brazing respectively.

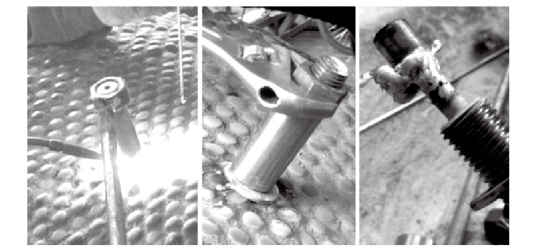

Brazing test:

The stress point welding test was carried out by brazing, and the base material was a common steel bar. After welding, there is no crack in the stud and the base metal welding joint is very firm (see Figure 1), therefore, it is appropriate to use the brazing method to weld the stress point and connect the stud and the nail-changing device.

To solve the difficulty of replacing the silver face stud of the high-pressure grinding machine, this paper provides you with a fast replacement device for the roller face stud of the high-pressure roller grinding machine.

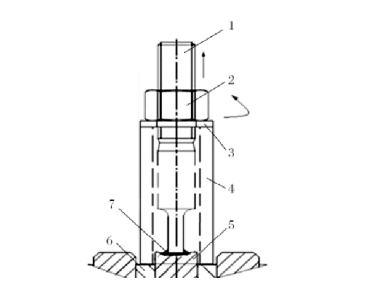

As shown in Figure 2, the device consists of connecting screw, nut, flat washer, and steel pipe. One end of the connecting screw is threaded, and the nominal diameter should be greater than the diameter of the stud, to avoid interference with the steel pipe when pulling out the stud. The other end is not threaded, and the diameter is smaller than the stud, which is convenient for subsequent welding. The nut is rotated on the threaded side and installed with a flat washer. When the broken stud and the lead screw are welded together, the nut is used to screw the connecting lead screw and give the stud a smooth axial tension; The steel pipe is sheathed on the non-threaded side, and the connecting screw is exposed.

Fig.2 Brazing welding test

1.Connecting screw 2. Nut 3. Flat washer 4. Steel pipe 5.Stud 6. Sleeve 7.The welding point

Experiment:

As shown in Figure 3, the abandoned stud extruding roll was used to carry out the test. The threaded end of the nail-changing device was welded to the stud on the roll surface, and the stud could be removed successfully by turning the nut with a wrench.

Fig.3 Structure and working principle of device of replacing stud

Fig.4 Test for stud replacement

If you are interested in CARBIDE STUDS and want more information and details, you can CONTACT US by phone or mail at the left, or SEND US MAIL at the bottom of the page.