Types Of Tungsten Carbide Buttons And Some Tips

Types Of Tungsten Carbide Buttons And Some Tips

Types of tungsten carbide buttons are:

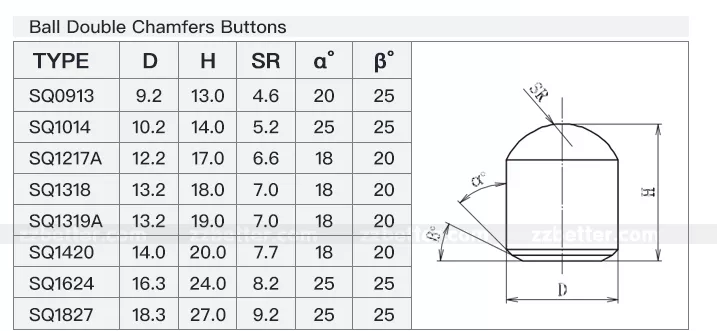

1. Spherical Buttons

Spherical button for setting rock hammer, DTH and roller cone bits for oil rigs in very hard rock formations.

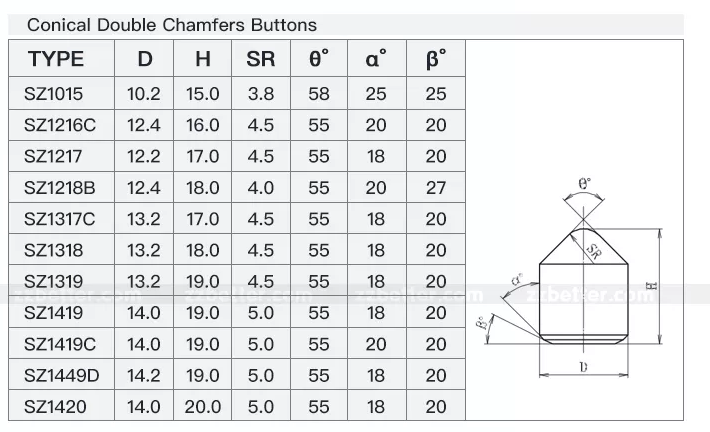

2. Carbide conical Buttons

Conical buttons for inserting rock drilling hammer bits, DTH bits and roller cone bits, suitable for medium hard rock formations.

3. Bullet buttons

Bullet buttons for inserting DTH and roller cone bits, suitable for hard rock formations.

Flat top teeth, suitable for roller cone bits, diamond bits, hole stabilizers, etc., reduce steel surface wear.

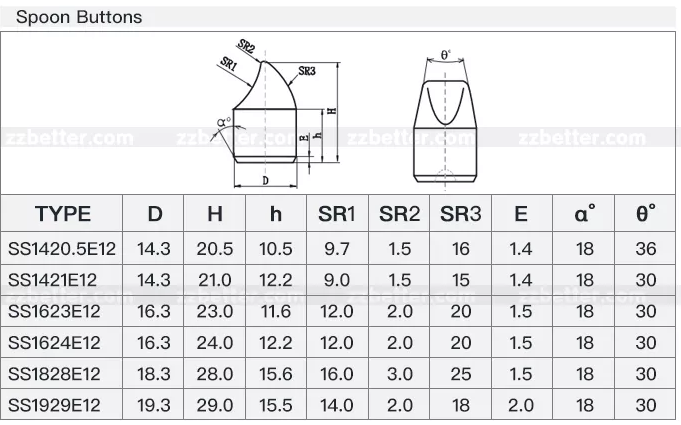

4. Spoon-shaped button

Spoon-shaped button for inserting roller cone bits for high speed drilling into soft rock formations.

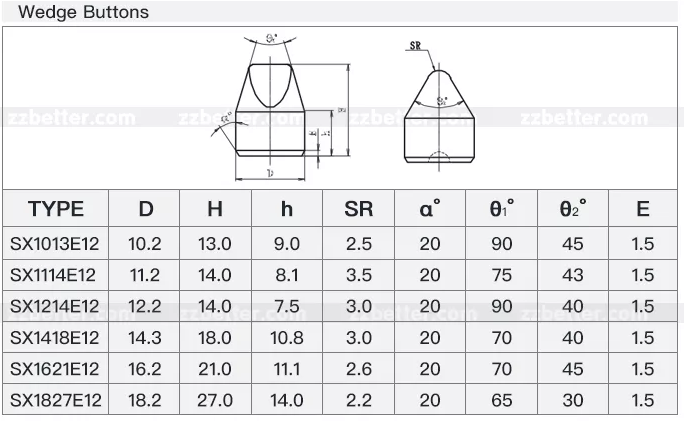

5. Wedge Buttons

Wedge-shaped buttons, used for inserting special-shaped DTH bits and roller cone bits, suitable for soft rock formations with high ROP and low broken teeth.

The above-mentioned cemented carbide button of various shapes have their respective ranges of use and working characteristics. What kind of cemented carbide button should be used based on the test and choose the appropriate cemented carbide button shape according to the actual situation.

Reasonable use of carbide buttons

In the process of rational use of cemented carbide buttons, the following points should be paid attention to:

1. Don't treat it casually because of wear resistance. Any drill bit needs to monitor its use at any time. Once abnormality is found, if it is repaired in time, the carbide button drill bit is no exception. We must always pay attention to whether it has "cracking" phenomenon or peeling. When this happens, it means that the wear of the drill affects its use, and it needs to be repaired. When the rock drilling speed of the rock drill drops significantly, we should also consider that it may be due to excessive wear of the drill.

2. The brute force should not be used during the operation. The propulsion force should be reduced to reduce the stress of the carbide button drill bit. At the same time, a large amount of water should be used for scouring to remove the impurities generated during the operation in time. Attention should also be paid to the use of flushing water, continuous flushing should be started, and the flushing should be started early when just working, otherwise it will cause the temperature of the drill tool to rise and then suddenly encounter water to cool down and cause cracks.

ZZBETTER has a complete range of cemented carbide ball teeth, and various sizes of cemented carbide mining buttons can be produced and customized.