Terminology of hard alloy(1)

Terminology of hard alloy(1)

To promote understanding of reports and technical writings about hard alloy, standardize the terminology, and explain the meaning of the technical terms in articles, we are here to learn the terms of hard alloy.

Tungsten Carbide

Tungsten carbide refers to sintered composites consisting of refractory metal carbides and metal binders. Among the metal carbides currently in use, tungsten carbide (WC), titanium carbide (TiC), and tantalum carbide (TaC) are the most common components. Cobalt metal is widely used in cemented carbide production as a binder. For some special applications, metal binders such as nickel (Ni) and iron (Fe)can also be used.

Density

Density refers to the mass-to-volume ratio of the material, which is also called specific gravity. Its volume also contains the volume of pores in the material. Tungsten carbide (WC) has a density of 15.7 g/cm³ and cobalt (Co) has a density of 8.9 g/cm³. Therefore, as the cobalt (Co) content in tungsten-cobalt alloys (WC-Co) decreases, the overall density will increase. Although the density of titanium carbide (TiC) is less than that of tungsten carbide, it is only 4.9 g/cm3。 If TiC or other less dense components are added, the overall density will decrease. With certain chemical compositions of the material, an increase in pores in the material results in a decrease in density.

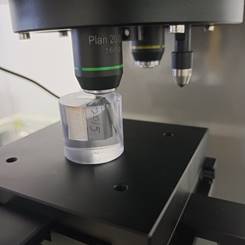

Hardness

Hardness refers to the ability of a material to resist plastic deformation.

Vickers hardness (HV) is widely used internationally. This hardness measurement method refers to the hardness value obtained by using diamond to penetrate the surface of the sample to measure the size of the indentation under a certain load condition. Rockwell hardness (HRA) is another commonly used hardness measurement method. It uses the penetration depth of a standard diamond cone to measure hardness. Both the Vickers hardness and the Rockwell hardness can be used for the hardness measurement of cemented carbide, and the two can be converted into each other.

Bending strength

Bending strength is also known as transverse breaking strength or flexural strength. The hard alloys are added as a simple support beam on two pivots, and then a load is applied to the centerline of both pivots until the hard alloy ruptures. The values calculated from the winding formula are used for the load required to break, and the cross-sectional area of the sample. In tungsten-cobalt alloys (WC-Co), the flexural strength increases with the cobalt (Co) content in the tungsten-cobalt alloys, but the flexural strength reaches a maximum when the cobalt (Co) content reaches about 15%. Flexural strength is measured by averaging several measurements. This value will also vary with the geometry of the sample, surface condition (smoothness), internal stress, and internal defects of the material. Therefore, flexural strength is only a measure of strength, and flexural strength values cannot be used as a basis for material selection.

Porosity

Cemented carbide is produced by powder metallurgy process by pressing and sintering. Due to the nature of the method, trace amounts of porosity may remain in the metallurgical structure of the product.

The reduction in porosity can effectively improve the overall performance of the product. Pressure sintering process is an effective means to reduce porosity.