The Production Process of Water Jet Cutting Nozzle

The Production Process of Water Jet Cutting Nozzle

The waterjet cutting nozzle is an important part of the waterjet cutting machine. This part is made of pure tungsten carbide material.

Usually, the tungsten carbide product refers to the mixing of tungsten carbide powder with cobalt powder or other binder powder. Then it can be formed by an ordinary sintering furnace to make a tungsten carbide product with high wear resistance and high strength. However, to make a pure tungsten carbide product with ultra-fine density and higher hardness without a binder phase, it is shown that the ordinary sintering method is not feasible. But the SPS sintering method solves this problem.

Spark Plasma Sintering (SPS), also known as "Plasma Activated Sintering" (PAS), is a new technology for preparing functional materials. This technology makes binderless tungsten carbide rods, and the water jet focusing tubes are made of these pure tungsten carbide rods.

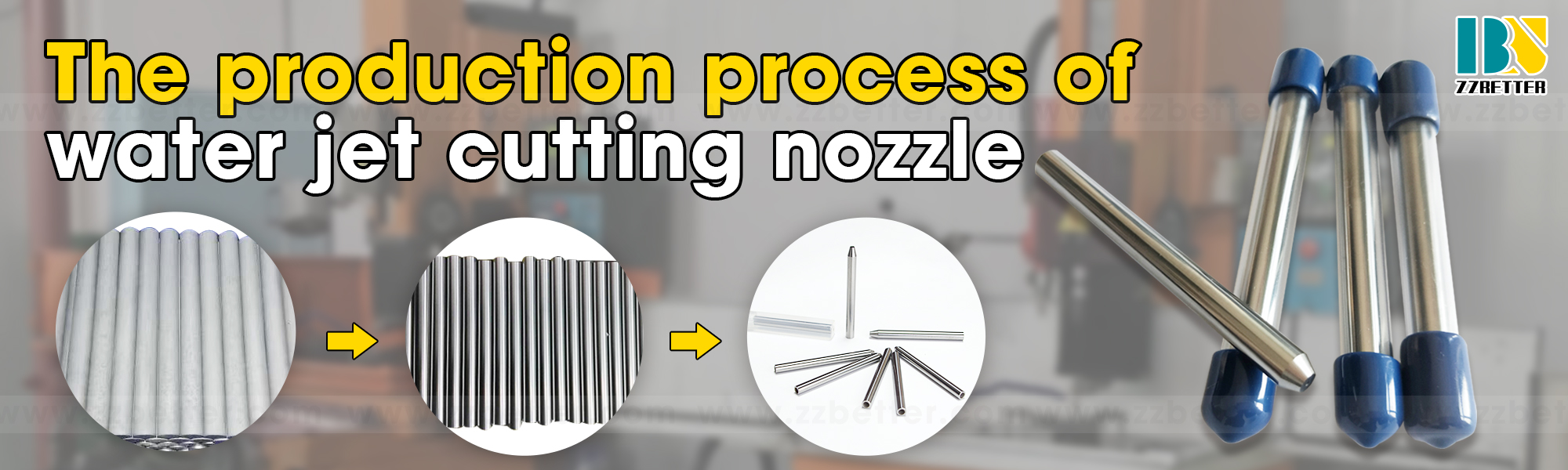

Processing blank tungsten carbide bar to the finished waterjet cutting nozzle’s steps:

1.Grinding surface. The tungsten carbide water jet nozzle diameter is usually required to grind to 6.35mm, 7.14mm,7.97mm,9.43mm, or other diameters clients need. And one end grinds a slope as the “nozzle” shape.

2.Drilling hole. The rods on one end drill a short cone hole at first. Then use a wire cut machine to make the small-size hole which usually is 0.76mm,0.91mm,1.02mm, and other hole sizes clients need.

3.Checking size. Especially check the waterjet nozzle hole size and concentricity.

4.Marking dimensions. Waterjet nozzle tube has many sizes. So marking the size on the carbide tube body is convenient to choose the correct waterjet focusing tube.

5.Packing. The water jet nozzle has high density and hardness.

However, as the waterjet cutting nozzle is made of pure tungsten carbide rods which are without any binder, the nozzle is easily fragile like glass. So the waterjet cutting tube is always packed in a separately plastic box to avoid hitting other tools.

If you are interested in water jet and want more information and details, you can CONTACT US by phone or mail at the left, or SEND US MAIL at the bottom of the page.