The performance of the PDC cutters

The performance of the PDC cutters

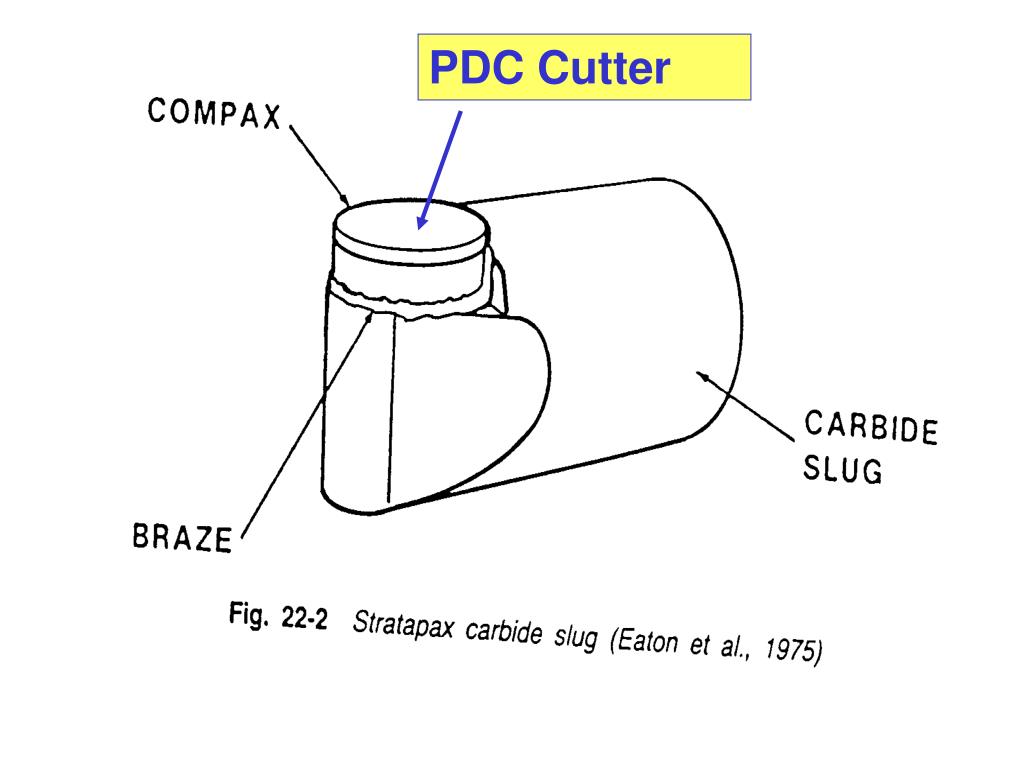

The research and development of PDC cutters were developed in many countries in the 1970s. The representative is the "stratapax" by G.E company, The "syndrill" by the DeBeers company, and the "Claw Cutter" by Sandvik.

The performance of the above PDC cutters, no matter in wear resistance, impact toughness, or thermal stability, all represent the world's advanced level at that time.

The performance of the PDC cutter mainly refers to the below indicators:

1. Wear resistance (also known as wear ratio),

2. Anti-impact toughness (joule),

3. Heat stability

After a large time of tests for the PDC cutter, we discovered the level of PDC cutters in our country is as below:

The mid-1990s to 2003: wear resistance is 8 to 120,000 (10 to 180,000 abroad);

The impact toughness is 200 ~ 400 j (more than 400 j abroad).

The change in thermal stability is: after sintering at 750 ° C (under reduction conditions), the Wear ratio is shown to rise by 5% to 20% for some domestic manufacturers, and the impact toughness doesn’t have a big change. Some manufacturers have declined on wear ratio and anti-impact toughness.

To sum up, the hardness, wear resistance, impact toughness, and thermal stability of our country’s PDC cutters have approached and reached the international advanced level, laying a foundation for further drilling into medium-hard rocks with PDC cutters.

We call the PDC cutter with high hardness, high wear resistance, high impact toughness, and high thermal stability the four-high PDC cutters. Drilling with high-quality PDC cutters will drive the comprehensive development of drilling projects

The benefits of drilling soft to medium-hard rock formations, especially hard rock formations, by using a composite drill bit are:

1. The efficiency of rock crushing is greatly improved

2. High efficiency and shorten the construction period

3. Promote the renewal of drilling equipment.

4. The use of high-quality PDC cutters promotes the change of the structure of the diamond bit and the design of hydraulic parameters.

If you are interested in tungsten carbide products and want more information and details, you can CONTACT US by phone or mail at the left, or SEND US MAIL at the bottom of the page.