Things You Have To Know About PDC Drill Bits

Things You Have To Know About PDC Drill Bits

Polycrystalline diamond compact (PDC) is one of the hardest materials in the world, which is harder than tungsten carbide. Although PDC has enough hardness to apply in modern industry, they are too expensive. Tungsten carbide is better than PDC material economically when the rocks are not stiff. But PDC drill bits, of course, have their advantages since they are popular in mining construction.

What is a PDC drill bit?

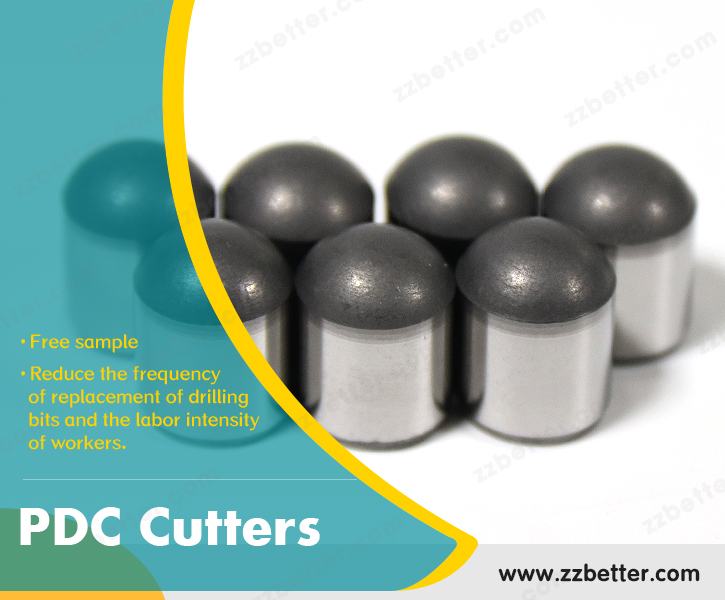

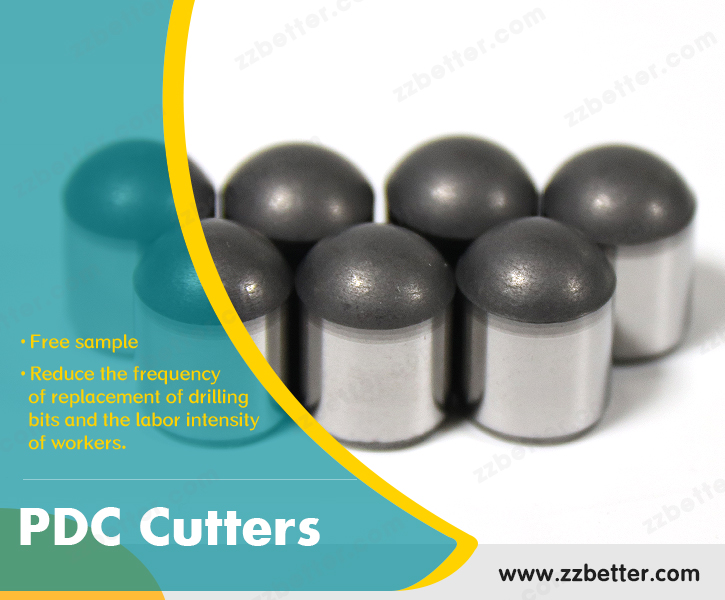

As we all know, tungsten carbide buttons are used to insert into a drill body to form a drill bit. PDC drill bits have PDC cutters on them. PDC cutters are made of tungsten carbide PDC substrates and PDC layers under an environment of high pressure and high temperature. The first production of PDC drill bits appeared in 1976. After that, they become more and more popular in many drilling industries.

How is the PDC drill bit made?

PDC drill bit is from tungsten carbide PDC substrates and PDC layers. PDC substrates come from high-quality tungsten carbide powder, experiencing mixing, milling, pressing, and sintering. PDC substrates have to be combined with PDC layers. With the catalyst of cobalt alloy under high temperature and high pressure, which can help bond diamond and carbide, the PDC cutter can be stiff and durable. When they cool down, the tungsten carbide shrinks 2.5 times faster than the PDC layer. Under an environment of high temperature again, the PDC cutters will be forged into the drill bits.

Applications of the PDC drill bits

Nowadays, the PDC drill bits are usually applied in the following situation:

1. Geological exploration

The PDC drill bits are suitable for geological exploration on soft and medium hardness rock layers because of their high hardness.

2. On coal field

When the PDC drill bits are applied to the coalfield, they have used for drilling and mining the coal seam. The PDC drill bits perform high efficiency.

3. Petroleum exploration

PDC drill bits can also be used for petroleum exploration to drilling in oil and gas fields. This kind of PDC drill bit is always the most expensive one.

Advantages of the PDC drill bits

1. High resistance to impact;

2. Longer work lifetime;

3. Not easy to damage or fall out;

4. Save customers’ costs;

5. Higher work efficiency.

If you are interested in PDC cutters and want more information and details, you can CONTACT US by phone or mail at the left, or SEND US MAIL at the bottom of the page.