Types of DTH button bit and buttons on it

Types of DTH button bit and buttons on it

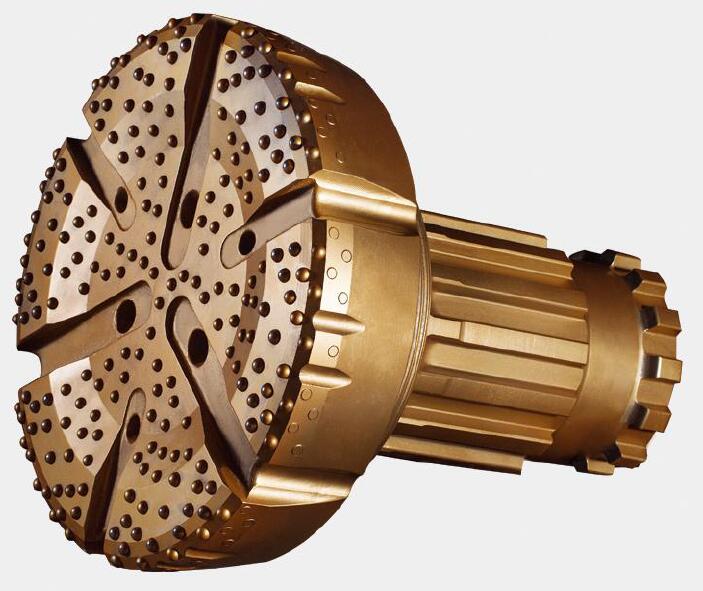

Nowadays, tungsten carbide productions appear in different working conditions as tungsten carbide tools or a tungsten carbide material attached to other larger tools. Down-The-Hole (DTH) button bit always requires high-quality tungsten carbide buttons with resistance to high impact and abrasive wear. DTH button bits are used for DTH drilling to produce a straight hole or a direction hole with a large diameter. They can also be used to bore into hard and robust rock layers. In this article, we are going to talk more about the DTH button bits and the tungsten carbide buttons used on them.

Types of DTH Button Bits

According to the different faces of the button bits, the DTH button bits can be divided into three kinds of button bits. They are concave button bits, convex button bits, and flat-faced button bits.

1. Concave button bits

The concave button bits are characterized by the concave and rounded faces on the button bit faces. The inner row and the outer row are all inserted with tungsten carbide buttons. And the inner row is inserted to protect the outer row from much wear. Generally speaking, concave button bits are more likely to deal with the very hard drilling formation.

2. Convex button bits

Contrary to the concave button bits, the convex button bits have convex and rounded outward on the button bit faces. They are more suitable for soft or medium hard rocks, like limestone, shale, or rocks that are already worn out. With a center outward, the convex button bits will have a better penetration rate.

3. Flat-faced button bits

Flat-faced button bits don’t have the outward or the inward on the tungsten carbide button bit faces but are just flat. They are applied for digging hard formations like granite, basalt, or hard limestone.

Tungsten Carbide Buttons

Tungsten carbide buttons on the DTH button bits are made of WC powder and some binder like cobalt. After successive processes like mixing, milling, pressing, and sintering, tungsten carbide buttons are equipped with high hardness, resistance, and durability. With tungsten carbide buttons on it, the DTH button bits are more powerful.

ZZBETTER Tungsten Carbide always puts a high quality on the first role. If you are interested in tungsten carbide buttons and want more information and details, you can CONTACT US by phone or mail at the left, or SEND US MAIL at the bottom of the page.