What is Tungsten Carbide for Hardfacing

What is Tungsten Carbide for Hardfacing

Tungsten carbide Hardfacing is a process by which a coating of tungsten carbide is applied to the surface of components. This form of Hardfacing offers good resistance to corrosion and excels in maintaining its hardness at elevated temperatures.

About hardfacing, Tungsten Carbide (sometimes referred to as Tungsten, Carbide, Hardmetal, cemented carbide, hard alloy, Sintered metal) can be in several different forms. Wolfram (Atomic 74) is an element mined from Ammonium Para Tungsten or APT. After mining and processing, it is used in powder metallurgy to create Sintered metal shapes.

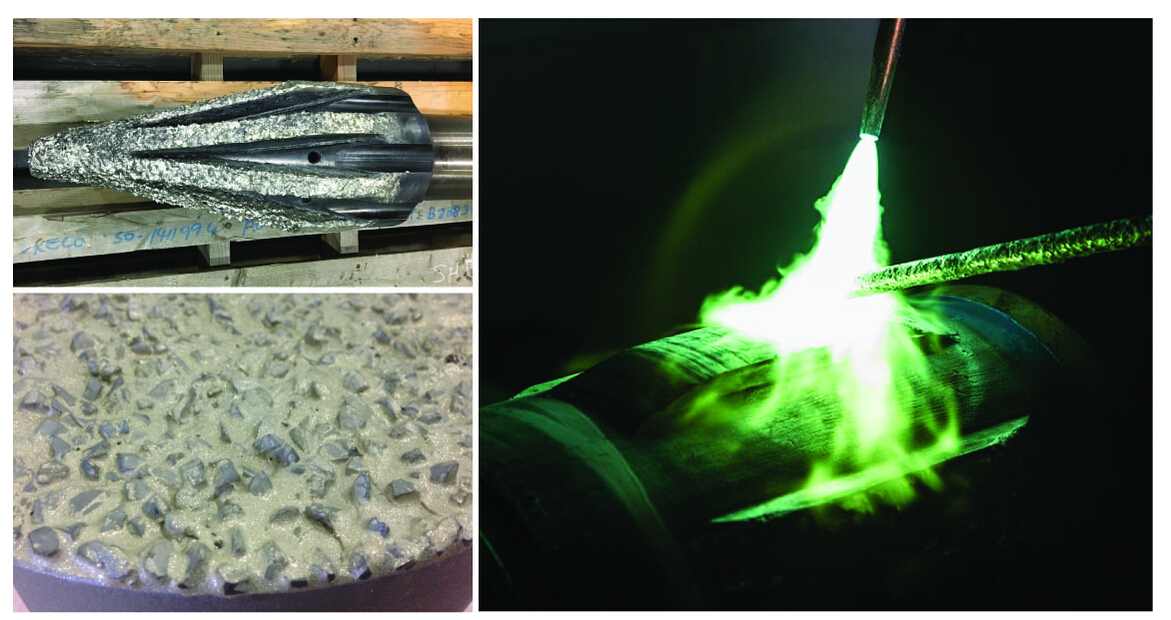

These shapes may be milling inserts, dies, drills, end mills, wear inserts, and an unlimited number of shapes only limited by the imagination. Pure tungsten can be melted at just over 6200 degrees and made into ingots to be crushed into W2C or 'Cast Carbide'. The cast is used in hardfacing applications through spray powder, tube metal, and a few specialized application procedures.

About Sintered - after tungsten carbide products can't work again, they will be recycled, and pieces of 'Carbide' are crushed to be used in hardfacing applications. The crushed metal is sized from 1/2" particles to minus 200 (<200, or 200 down). The larger particles are processed into Composite rods with the addition of a weldable or braze matrix to the particles. The smaller particles are used in the process. This process allows the welder to drop particles of Carbide in a molten puddle of welding wire in a continuous flat application. Many large earth-engaging companies use this method of hardfacing. It is also a widely used application in the oilfield termed 'Hardbanding'.

Tungsten carbide is a high-density material that is suitable for abrasive wear applications. This form of Hardfacing offers excellent corrosion resistance and excels in maintaining its hardness at elevated temperatures.

Tungsten carbide is a more expensive process than chrome carbide hardfacing but is much more wear-resistant and is, therefore, more suitable for abrasive applications. It also offers excellent corrosion resistance.

ZZBETTER provides a fast-turnaround tungsten carbide hardfacing material to companies for junk mill, stabilizers, rotary shoes, reamers, milling shoes, grinding shoes, foundation coring, wear pads, and screw feeders.

If you are interested in tungsten carbide products and want more information and details, you can CONTACT US by phone or mail at the left, or SEND US MAIL at the bottom of the page.