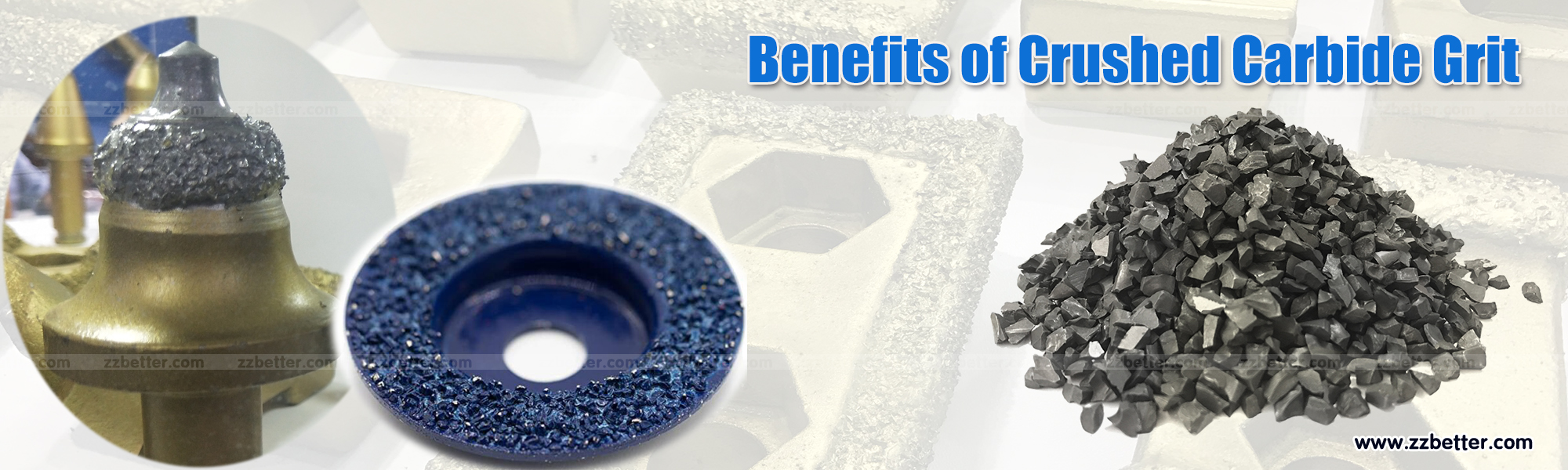

Benefits of Crushed Tungsten Carbide Grit

Benefits of Crushed Tungsten Carbide Grit

Tungsten carbide grits are produced to extend work life and increase efficiency.

It is an efficient way to protect machinery and its parts by increase significantly the longevity of those cost parts, and reducing the cost involved with unprotected parts.

Our cemented carbide chips provide long-lasting protection in aggressive wear applications from wear. After hard-facing, an overlay of tungsten grit is applied to a base metal. The mesh distribution can be customized to achieve the desired balance of protection from abrasion and impact. Our high-quality crushed carbide grits are preferred over traditional hard-facing materials because of their superior wear-resistant properties. It is time-tested and proven to be one of the most effective solutions to reduce product wear.

1. Applying crushed carbide grit to a new part will improve its wear resistance

2. Applying carbide welding tips to a used part will restore its worn-down surface.

3. Protecting costly parts such as cutting edge blades, bucket teeth, trencher teeth, wood grinding teeth, and other parts

4. Industries utilizing our tungsten carbide grit wear-resistant solutions

5. Wear parts are costly, and enhancing their protection through the application of crushed carbide tips extends the life of the wear part, helps reduce downtime, and increases the production efficiency.

Particular pieces of equipment and wear parts that are enhanced in terms of abrasion or impact resistance include tillers, rippers, sweeps, loaders, graders, milling attachments, shredders, stump grinders, debarkers, drill collars, drill pipes, and tubular.

Companies in industries benefiting from the use of the crushed carbide wear-resistant solutions include earthworks, wood & stone, agricultural, drilling & trenching, forestry, oil & gas, mining & construction.

ZZbetter carbide provides certificates of analysis showing the particle size distribution of your tungsten carbide grit.

Our tungsten grit products can be custom-made to meet your particular applications.

We offer "mixed grade" and "uncoated" tungsten grit products

We make tungsten carbide grits suitable for our customers' specific applications

All grit sizes and mixtures are available

If you are interested in tungsten carbide products and want more information and details, you can CONTACT US by phone or mail at the left, or SEND US MAIL at the bottom of the page to get an extra layer of protection, increase efficiency and decrease your downtime with our tungsten carbide grit wear-resistant solutions.