Features and Applications of Carbide Wear Parts

Features and Applications of Carbide Wear Parts

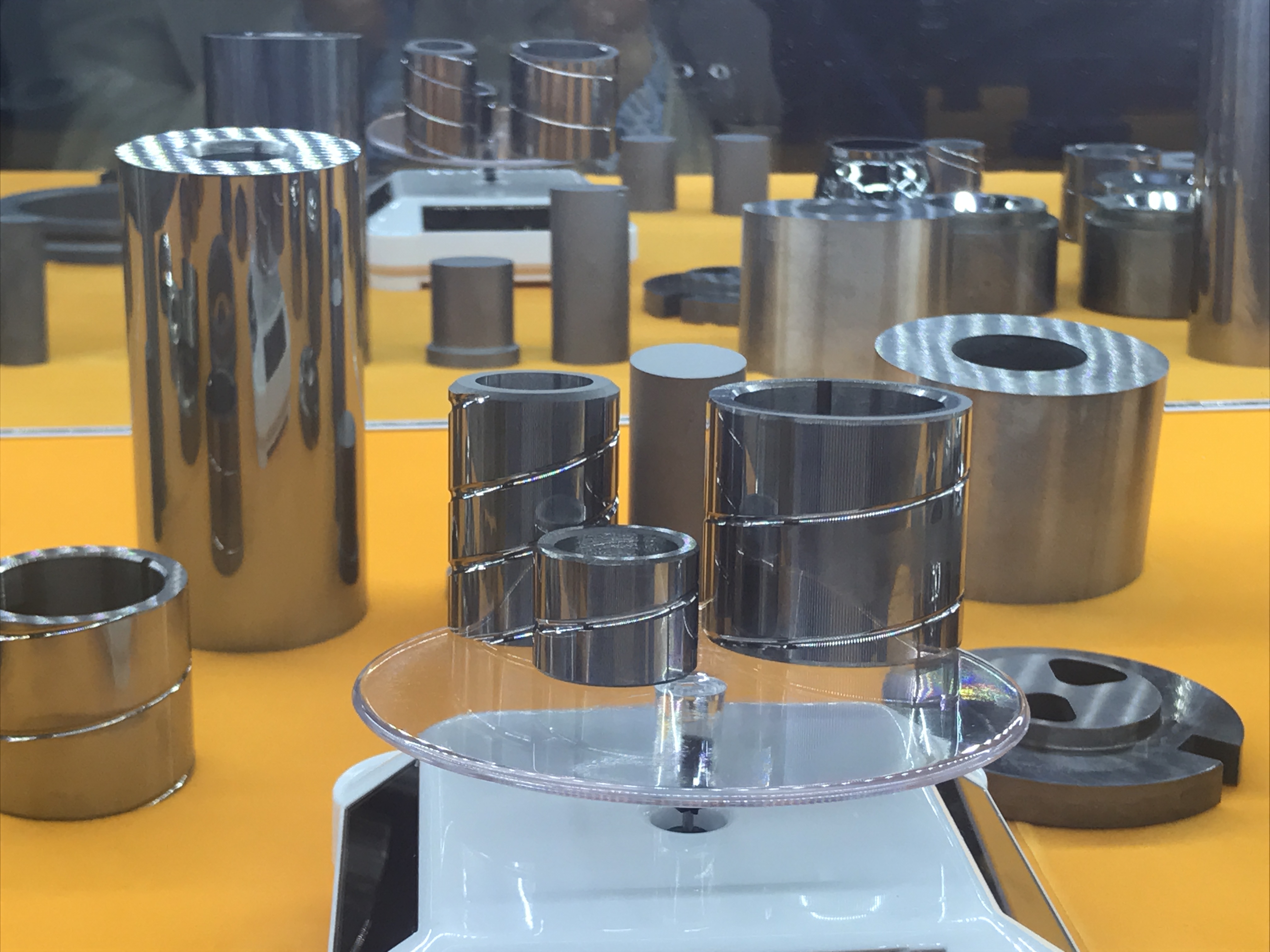

Wear-resistant components made from tungsten carbide as raw materials can be referred to as carbide wear parts, which have high hardness, strong wear resistance, and wide industrial applications. Excellent wear resistance and high hardness make them suitable for manufacturing mechanical parts and drawing die featuring high-temperature resistance, friction resistance, and corrosion resistant.

Applications of carbide wear parts

The tungsten carbide wear parts have a series of excellent performance, good wear resistance, high strength and toughness, heat resistance, and corrosion resistance, especially their high hardness and excellent wear resistance, providing powerful product support and excellent performance for industrial production, helping improve production efficiency and extend the service life of the equipment.

1. Suitable for making cast iron rolls and high-nickel-chromium rolls to repair molded cutters.

2. Used for making unloading plates, stamping die, convex mold, electronic level molding, and other stamping dies.

3. In the pump, compressor, and mixer, the tungsten carbide seal is applied as a mechanical sealing surface.

4. Carbide wear parts can be used on the metal ring in the spinning and weaving industry to prevent rumors and displacement of enantiomers from rotating at high speeds and allows the machine to operate smoothly.

What is the commonly used carbide wear parts?

Tungsten carbide products used as wear-resistant parts include nozzle, guide rail, plunger, tire anti-slip nail, shovel snowboard, sweeping shovel, rotary seal ring, grinding mandrel, various pump parts, valve parts, seals, etc.

Carbide wear parts can be widely used as the carbide roller, precision molding & optical molds, stamping molds, drawings, seal ring, piston, bearing journal, and surface hardening welding, spray materials, etc.

ZZBETTER has been committed to providing high-performance carbide products for industrial mechanical production. ZZBETTER relies on high production technology, professional production equipment, and more than 20 years of experience, providing customers with high-quality carbide products based on the drawings and selecting superior materials to maximize the use requirements of customers for carbide wear parts.

If you are interested in tungsten carbide products and want more information and details, you can CONTACT US by phone or mail at the left, or SEND US MAIL at the bottom of the page.