Features and Uses of Cemented Carbide

Features and Uses of Cemented Carbide

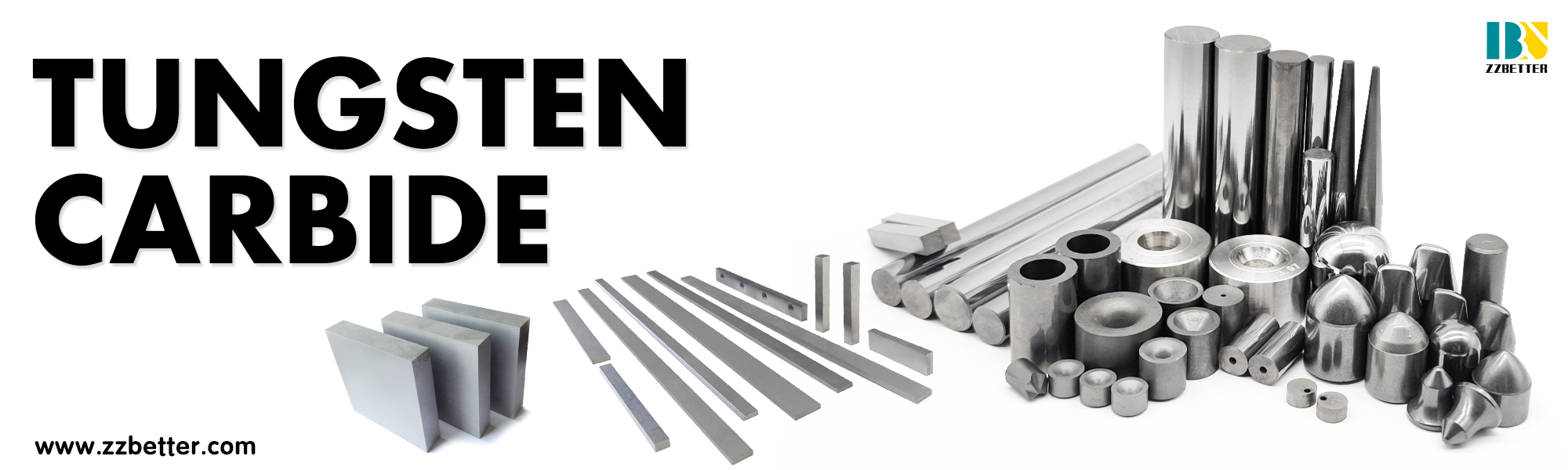

Features of tungsten carbide

Tungsten carbide has high hardness and wear resistance. The cutting speed of carbide tools is 4 to 7 times higher than that of high-speed steel and 5 to 80 times the higher service life. Carbide products can cut hard materials of about 50HRC. The articles will introduce some important knowledge about cemented carbide.

Material properties of tungsten carbide

Cemented carbide is mainly a micro-sized powder of carbides (WC, TiC) of high-hardness refractory metals. The main components are powder metallurgical products sintered in a vacuum furnace or a hydrogen reduction furnace with cobalt (Co), nickel (Ni), and molybdenum (Mo) as the binder.

The matrix of cemented carbide is composed of two parts: one part is the hardening phase, and the other part is the bonding metal.

The hardened phase is the carbide, such as tungsten carbide, titanium carbide, and tantalum carbide. Its hardness is very high. Its melting points are above 2000°C, and some even exceed 4000°C. The existence of the hardening phase determines the extremely high hardness and wear resistance of carbide.

Tungsten carbide WC grain size requirements for cemented carbide use different grain size WC according to different applications.

This article mainly introduces three uses of cemented carbide:

1. Tungsten carbide for making carbide cutting tools

Carbide cutting tools are widely used for metal cutting and machining. Fine machining alloys such as foot cutter blades and V-CUT knives use ultra-fine, sub-fine, and fine-grained WC. Rough-machining alloys use medium-grain WC. Gravity cutting alloys and heavy-duty cutting alloys use medium and coarse Granular WC as raw material.

2. Cemented carbide for making carbide mining tools

The rock has high hardness and a high impact load. Coarse WC is adopted, and the rock impact is small with a small load. A medium-sized WC is used as raw material.

3. Hard alloy for making carbide wear-resistant parts

When emphasizing its wear resistance, compression resistance, and surface finish, WC with different sizes is used as raw material, and medium and coarse-grained WC raw material is used as the main material.

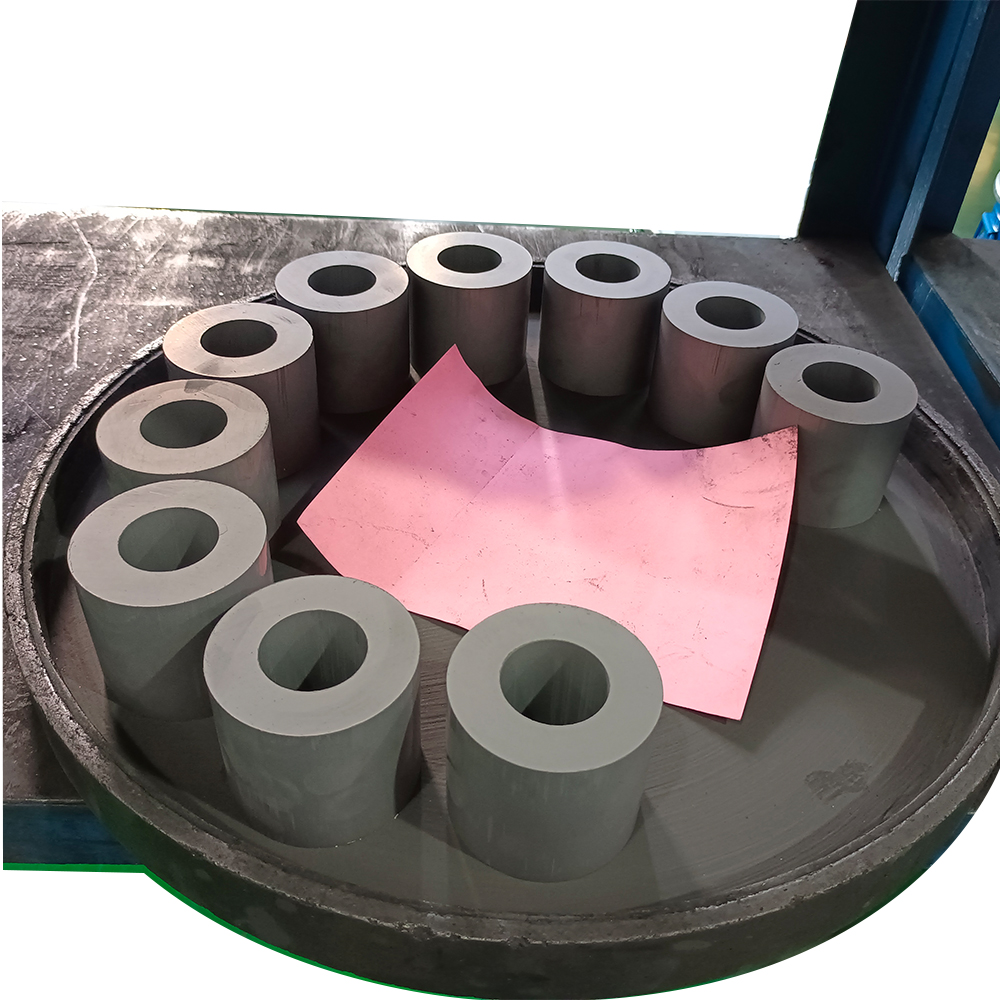

4. Hard metal for making tungsten carbide Dies

The carbide dies have several tens of times longer service life than steel molds. The carbide mold has high hardness, high strength, corrosion resistance, high-temperature resistance, and a small expansion coefficient, generally composed of tungsten cobalt.

If you are interested in tungsten carbide products and want more information and details, you can CONTACT US by phone or mail at the left, or SEND US MAIL at the bottom of the page.