How To Produce PDC Cutters

How to produce PDC cutters

PDC Cutter was invented firstly by General Electric (GE) in 1971. it is introduced commercially in 1976 after it is proven much more efficient than crushing actions of carbide button bits. PDC bits now occupy more than 90% of the total drilling footage in the world. But do you know how the PDC cutters are produced? I'd like to share some information with you here.

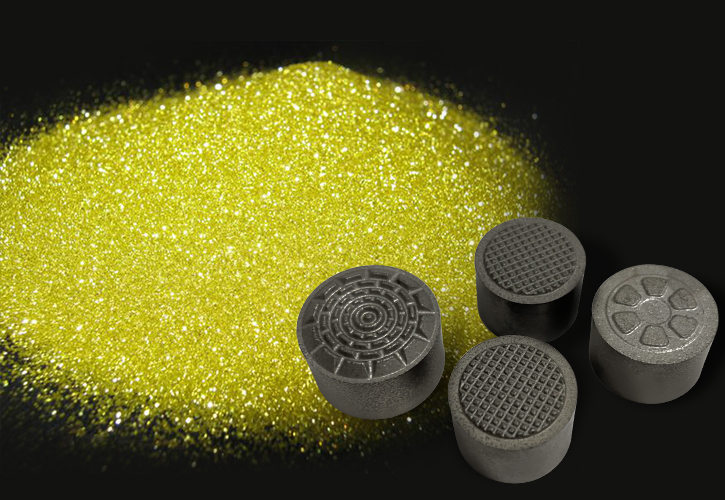

Materials

select premium diamond, crush and shape it again, making the particle size more uniform, purifying the diamond material. For tungsten carbide substrate we use the high-quality virgin powder and suitable carbide grade with high impact resistance.

HTHP sintering

1. professional operator and advanced facilities to produce the PDC cutters

2. check the temperature and pressure in real-time and adjust in time. The temperature is 1300 - 1500 ℃. The pressure is 6 - 7 GPA.

3. Producing one piece of PDC Cutters will need around 30 minutes in total.

First pieces inspection

Before the mass production, inspect the first piece to see whether it meets the customer's requirements for dimension and performance.

Grinding

1. dimension grinding: grind the outer diameter and height. use the cylindrical grinder to perform external grinding to the product billet. Because the material may have fluctuated during the super-high pressure and high-temperature synthesis, the obtained product may not have a perfect shape and meet the requirement of product appearance, and a perfect cylinder has to be obtained through external grinding.

2. chamfer grinding: the chamfer should be about 0.1-0.5mm with an angle of 45; the chamfer can be ground to different degrees in accordance with the customer's requirement.

Inspection of finished products

To ensure all PDC cutters are qualified and consistent, we should inspect the final PDC cutters. The inspection of items such as appearance, dimensions, and physical performance should be conducted, then classify and pack the products after inspected to be qualified. This is an important step to guarantee product quality; measurement of the thickness of the polycrystalline diamond should be emphasized during the product inspection.

Packing

The appearance and dimensions of the outgoing product should meet the industrial standard, in addition, the product appearance and dimensions should not change during long-distance transportation. First into a plastic box, then into a carton.50 pieces in every plastic box.

At ZZbetter, we can offer a wide range of specific cutters.