The 4 Facts That You Have To Know About The Hard-Facing

The 4 Facts That You Have To Know About The Hard-Facing

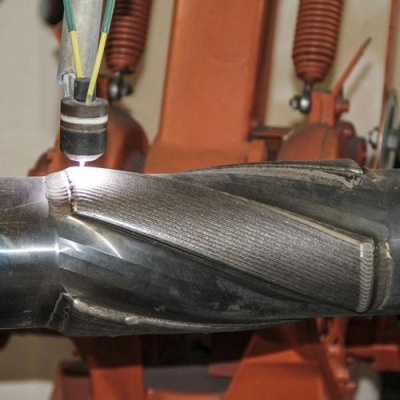

Hard facing, also called hard surfacing, is a metalworking process of applying tougher metals, high-temperature alloys, ceramics and other overlays to base metals to enhance standard wear, corrosion, hardness and other physical and chemical characteristics of the base metal.

When to Hard face?

Hard facing always is applied during all life cycles of a fabricated or machine's part. In general, hard facing is applied.

On new parts to increase the wear resistance.

On used, worn-down surface back to tolerance, prolong the working life.

On functional equipment to extend the life of fabricated components as part of maintenance program.

How is the Hard facing applied?

There are a lots of methods to apply hard facing. Those methods are applied to different applications. So no one method is superior to others, rather the method is recommended based on the intended purpose of the hard facing. Some of the common welding methods include:

1. Shield Metal Arc Welding (SMAW)

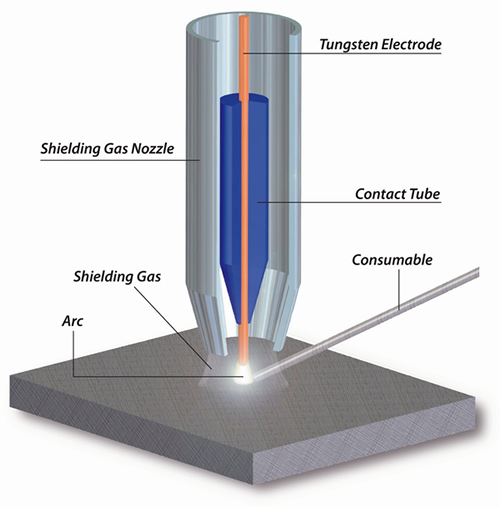

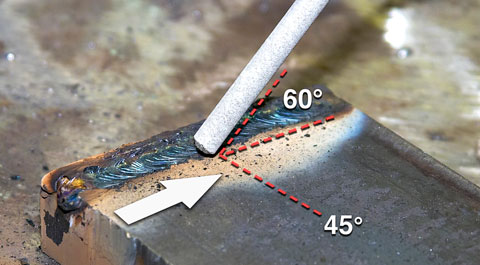

2. Gas Metal Arc Welding (GMAW)

3. Oxyfuel Welding (OFW)

4. Submerged Arc Welding (SAW)

5. Electrical Welding (ESW)

6. Plasma Transferred Arc Welding (PTAW)

7. Thermal Spraying

8. Cold polymer compounds

9. Laser Cladding

Hard facing has been incorporated into the procurement and maintenance programs for a variety of industries including, but not limited to, Steel, Cement, Mining, Petrochemical, Power, Sugarcane and Food, Process Chemical, as well as general manufacturers.

The Materials and Costs of the hard facing

The hard-facing technique for a job depends on the geometry of the part and the relative cost of the hard-facing method. Costs can vary with the deposition rate of the material.

These cost variations can be summarized as follows:

• Flux-cored arc welding (FCAW) 8 to 25 lb/hr

• Shielded Metal Arc Welding (SMAW) 3 to 5 lb/hr

• Gas Metal Arc Welding (GMAW), including both gas-shielded and open arc welding 5 to 12 lb/hr

• Oxyfuel Welding (OFW) 5 to 10 lb/hr

If you are interested in learning more about hard-facing methods, applications, or looking for a consultation, contact zzbetter carbide .

#HARDFACING #LASER #CLADDING #PLASMA #SPRAY #POWDER #METAL #WELDING #THERMAL #SPRAY #TIG #WELDING #CARBIDE