The Production Technology of Hard Alloy

The Production Technology of Hard Alloy

Hard alloy is a kind of hard material which is composed of refractory metal hard compound and bonded metal; hard alloys, are hard materials with high wear resistance and toughness, which are produced by powder metallurgy; because of its excellent performance, cemented carbide is widely used in machining, wear-resistant parts, mining, geological drilling, oil mining, machinery parts and other fields.

Hard Metals Production Technology deals with the production technology and investigation of the structure and physical-mechanical properties of hard metals. One of the important elements in technical progress is the national production of hard metals. The development and introduction of highly efficient hard metals ensure that labor productivity will increase in metalworking, mining, oil, and coal industries.

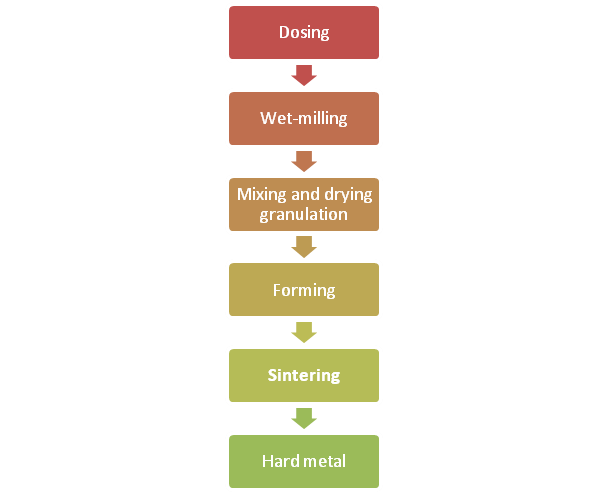

The production process of cemented carbide is as follows: mixture preparation, pressing and forming, sintering. There are 3 processes in total.

Flow chart of hard alloy production process

The raw materials and a small amount of additives required are weighed and loaded into the rolling ball mill or the stirring ball mill. In the ball mill, the raw materials are refined and evenly distributed. After spray drying and vibration sifting, the mixture with certain composition and particle size requirements is made to meet the needs of pressing forming and sintering. After pressing and sintering, the hard alloy blanks are released and packaged after quality inspection.

Hard metal blanks

Processing method of rough cemented carbide:

1. Internal and external thread processing: carbide thread processing should be processed by thread milling, cannot be directly processed with screw taps.

2. The processing of the inner groove: diamond grinding rod should be selected, and the amount of cutting each time is controlled to be about 20 to 30 um. The specific adjustment should be made according to the advantages and disadvantages of diamond grinding rod.

3. EDM

4. Welding processing: brazing, silver welding processing

5. Grinding processing: centerless grinding, internal grinding, surface grinding, tool grinding, the grinding wheel is generally diamond grinding wheel, the specific choice depending on the process requirements.

6. Laser processing: laser cutting forming, punching are available, but the thickness of the cutting is constrained by the power of the laser machine constraints.

If your tungsten carbide product becomes dull or "cloudy", you don't need to buy an expensive jewelry cleaner to shine and polish your tungsten jewelry. A simple mixture of soapy water and a clean cloth are the only items you need to clean this tough, scratch resistant metal. Also, silicon carbide is best for sharpening carbide.

If you are interested in tungsten carbide products and want more information and details, you can CONTACT US by phone or mail at the left, or SEND US MAIL at the bottom of this page.