Tungsten Carbide Plates

Tungsten Carbide Plates

Introduction to Cemented Carbide Plates

A tungsten carbide plate is one type of product that is made from tungsten carbide. Tungsten carbide strips are produced by powder metallurgical methods, ball milling, pressing, and sintering. The strips made out have excellent hardness, high wear-resistance, good modulus of elasticity, high compressive strength, good chemical stability(which can resistance to acids and high-temperature oxidation), low impact toughness, low coefficient of expansion, and thermal and electrical conductivity similar to that of iron and its alloys.

Tungsten carbide plate is also an excellent material for making high-temperature resistant parts, wear-resistant parts, anti-shielding parts, and corrosion-resistant parts. When using tungsten carbide plates, the appropriate material should be selected according to the application.

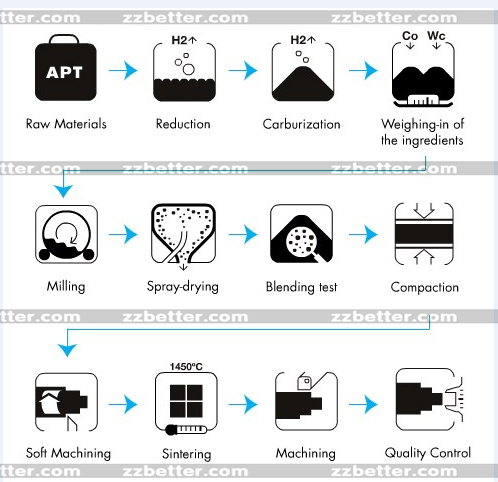

The production process of tungsten carbide plate

Powder→formulation according to application requirements→wet grinding→mixing→crushing→drying→sieving→then adding forming agent→drying again→sieving to make the mixture→granulating→ pressing→forming→sintering→forming (blank)→flaw inspection→packaging→warehousing.

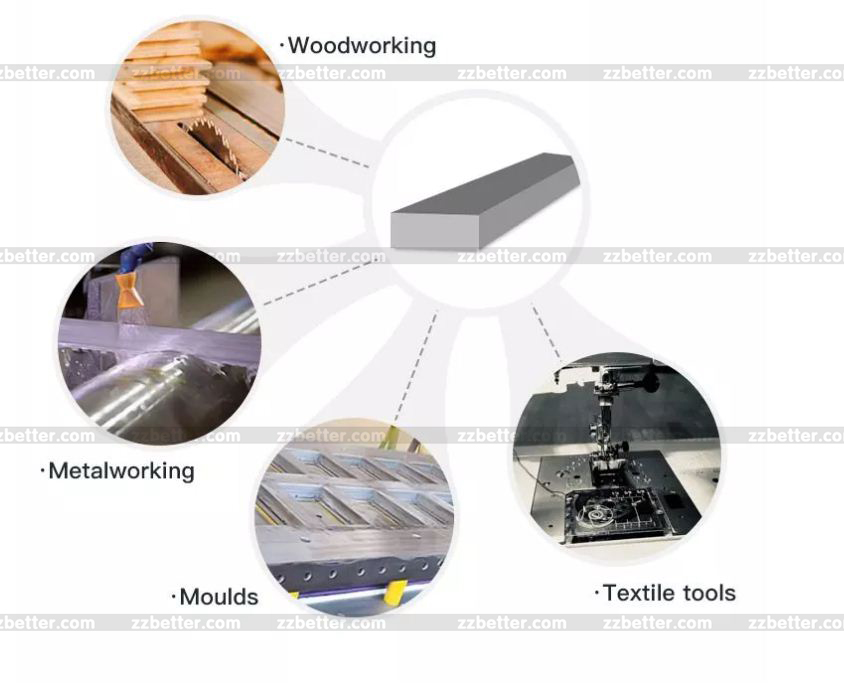

Applications of tungsten carbide plates

Cemented carbide sheet has excellent warp hardness, high hardness, good wear resistance, high modulus of elasticity, high compressive strength, good chemical stability (resistance to acids, alkalis, high-temperature oxidation), low impact toughness, low coefficient of expansion, thermal and electrical conductivity similar to that of iron and its alloys. Silicon steel sheet, cold-rolled sheet, suitable for making drawing dies, wear-resistant parts and die cores for stamping accessories and carbide automatic presses, etc., using good strength and impact toughness, lower wear resistance than the above alloys. Top forging dies for large loads, such as those used for screws, rivets, etc., also for stamping dies. Extrusion dies. Punching and cutting die etc.

Cemented Carbide Plate Details Applications

In just fifty years, the use of tungsten carbide turning tools has increased metal cutting speeds by a factor of two hundred, from ten meters per minute to over two thousand meters per minute. The heat-resistant tungsten carbide still retains good elasticity and mechanical strength and is generally used for thicker cuts, interrupted cuts, and poor part clamping. The coating gives good results in all types of materials up to HRC 50°. 1 to 2 times the longer service life and excellent impact resistance compared to normal tungsten carbide.

If you are interested in tungsten carbide products and want more information and details, you can CONTACT US by phone or mail at the left, or SEND US MAIL at the bottom of the page.