What Are the Advantages of Tungsten Carbide in Tooling?

What Are the Advantages of Tungsten Carbide in Tooling?

As we all know, tungsten carbide material is called “the teeth of industries”. It has very high hardness and high density, widely used in fields of cutting, drilling, and wear prevention.

Wikipedia explains tungsten carbide as this: “Tungsten carbide (chemical formula: WC) is a chemical compound (specifically, a carbide) containing equal parts of tungsten and carbon atoms. In its most basic form, tungsten carbide is a fine gray powder, but it can be pressed and formed into shapes through sintering for use in industrial machinery, cutting tools, abrasives, armor-piercing shells, and jewelry. Tungsten carbide is approximately twice as stiff as steel, with Young's modulus of approximately 530–700 GPa, and is double the density of steel—nearly midway between that of lead and gold. It is comparable with corundum (α-Al2O3) in hardness and can be polished and finished only with abrasives of superior hardness such as cubic boron nitride and diamond powder, wheels, and compounds.”

Tungsten carbide material has such high performance. What are the advantages when tungsten carbide material is used in the tooling field?

1. High hardness. The hardness of tungsten carbide varies from 83HRA to 94HRA. The high hardness makes tungsten carbide wears up to 100 times longer than steel in conditions including abrasion, erosion, and galling. Wear-resistance of tungsten carbide is better than that of wear-resistance tool steels.

2. Heat and oxidation resistance. To produce tungsten carbide, the carbide material will be sintered in the furnace at a high temperature of around 1400 centigrade. Tungsten-base carbides perform well up to about 1000°F in oxidizing atmospheres and 1500°F in non-oxidizing atmospheres.

3. Dimensional Stability. Tungsten carbide undergoes no phase changes during heating and cooling and retains its stability indefinitely. No heat treating is required.

4. Surface Finishes. The finish of an as-sintered part will be about 50 micro inches. Surface, cylindrical or internal grinding with a diamond wheel will produce 18 micro inches or better and can produce as low as 4 to 8 micro inches. Diamond lapping and honing can produce 2 micro inches and with polishing as low as 1/2 micro inch.

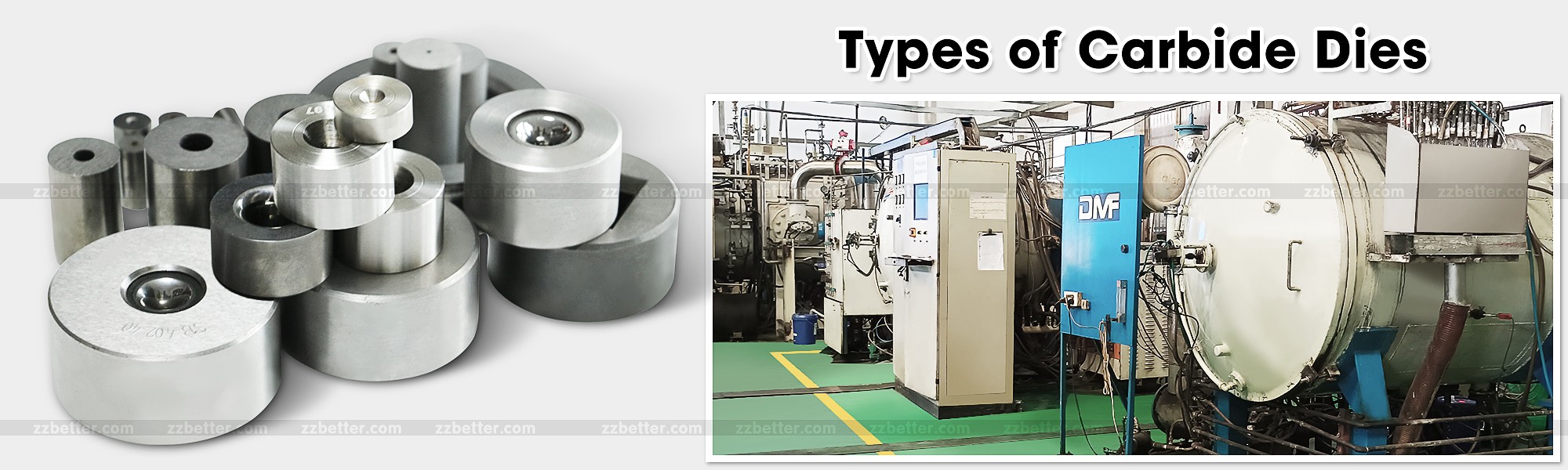

Zhuzhou Better Tungsten Carbide Company is a professional tungsten carbide provider. Tungsten carbide molds and tungsten carbide dies are one of our best sellers. ZZbetter can produce tungsten carbide cold heading dies, tungsten carbide hot forging dies, tungsten carbide drawing dies, and tungsten carbide nail dies. Above dies are widely used in many industries and replaced steel to be the top choice for tooling use. With the high hardness, high wear resistance, high bending strength, and stable performance in high and low temperatures, now the application of tungsten carbide is even broader than before. Our company will go on offering high-quality carbide solutions to our customers and potential customers with the hope that our carbide can help them achieve their value!

If you are interested in tungsten carbide products and want more information and details, you can CONTACT US by phone or mail at the left, or SEND US MAIL at the bottom of the page.