Advantages of Tungsten Carbide Rod with Single and Double Hole

Advantages of Tungsten carbide rod with Single and Double Hole

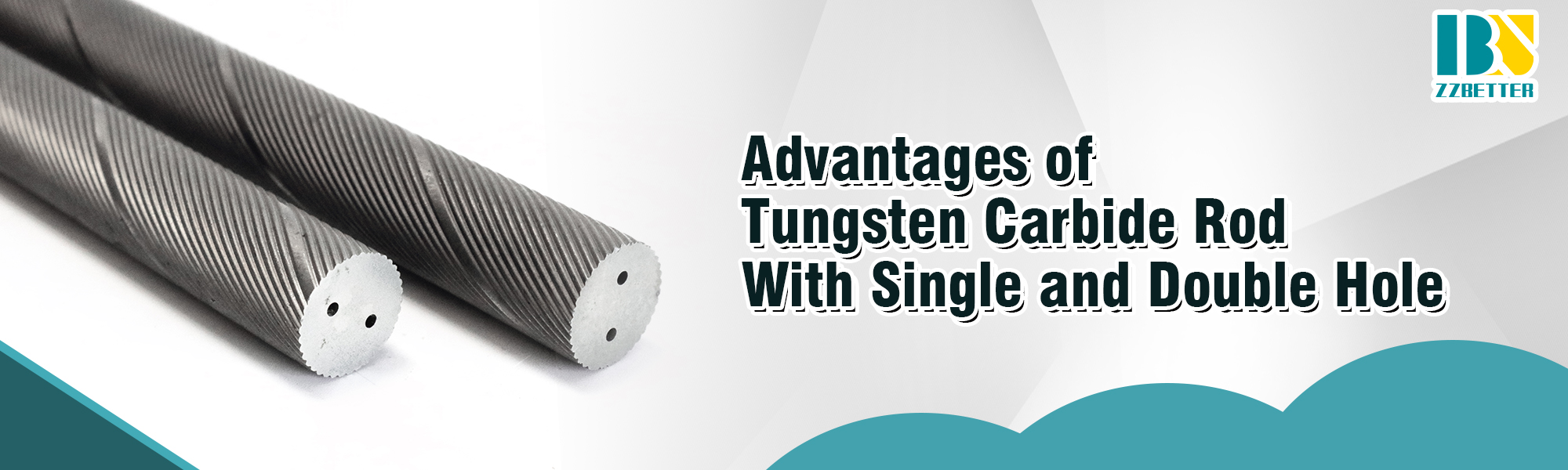

A tungsten carbide rod with a single hole is a type of tooling component made from tungsten carbide material that features a central hole running through the length of the rod. This design allows for specific applications in various industries such as machining, tool and die making, and other industrial sectors. A tungsten carbide rod with double holes is a tooling component made from tungsten carbide material that features two parallel holes running through the length of the rod.

A tungsten carbide rod with double holes provides advantages such as enhanced coolant flow, effective chip evacuation, and versatility in various machining applications where superior heat dissipation, chip management, and cutting efficiency are crucial.

Tungsten carbide rods with single and double coolant holes offer distinct advantages based on their design:

1. Single Coolant Hole:

Coolant Flow: A single coolant hole provides a focused coolant stream directly to the cutting edge, enhancing cooling and lubrication. This promotes efficient heat dissipation, reduces cutting temperatures, and improves tool life.

Chip Evacuation: While a single hole may not be as effective for chip evacuation compared to multiple holes, it still helps in removing chips from the cutting area, preventing chip recutting and maintaining machining quality.

Simplicity: Single coolant hole rods are often simpler in design and manufacturing, which may result in a more cost-effective solution for certain applications.

2. Double Coolant Holes:

Enhanced Coolant Flow: Double coolant holes provide increased coolant flow and coverage over the cutting area. This leads to improved cooling efficiency, better chip evacuation, and reduced heat build-up during machining operations.

Effective Chip Evacuation: The dual holes facilitate better chip removal, preventing chip jamming and allowing for smoother cutting processes. This results in reduced tool wear, improved surface finish, and overall enhanced productivity.

Versatility: Double coolant hole rods offer more versatility in coolant delivery and chip evacuation, making them suitable for high-speed machining applications or operations where effective heat dissipation is crucial.

Ultimately, the choice between tungsten carbide rods with single or double coolant holes depends on the specific machining requirements of the application. Single coolant hole rods are simpler and may be sufficient for basic cooling needs, while double coolant hole rods offer enhanced cooling and chip evacuation capabilities, making them ideal for more demanding or high-performance machining applications.

If you are interested in Tungsten Carbide Rod with Hole and want more information and details, you can CONTACT US by phone or mail at the left, or SEND US MAIL at the bottom of the page.