Benefits of Choosing Tungsten Carbide Cutting Blades

Benefits of Choosing Tungsten Carbide Cutting Blades

Tungsten carbide blades are made of tungsten carbide material. This material's performance is excellent. What are the benefits we can get from the carbide blade tools?

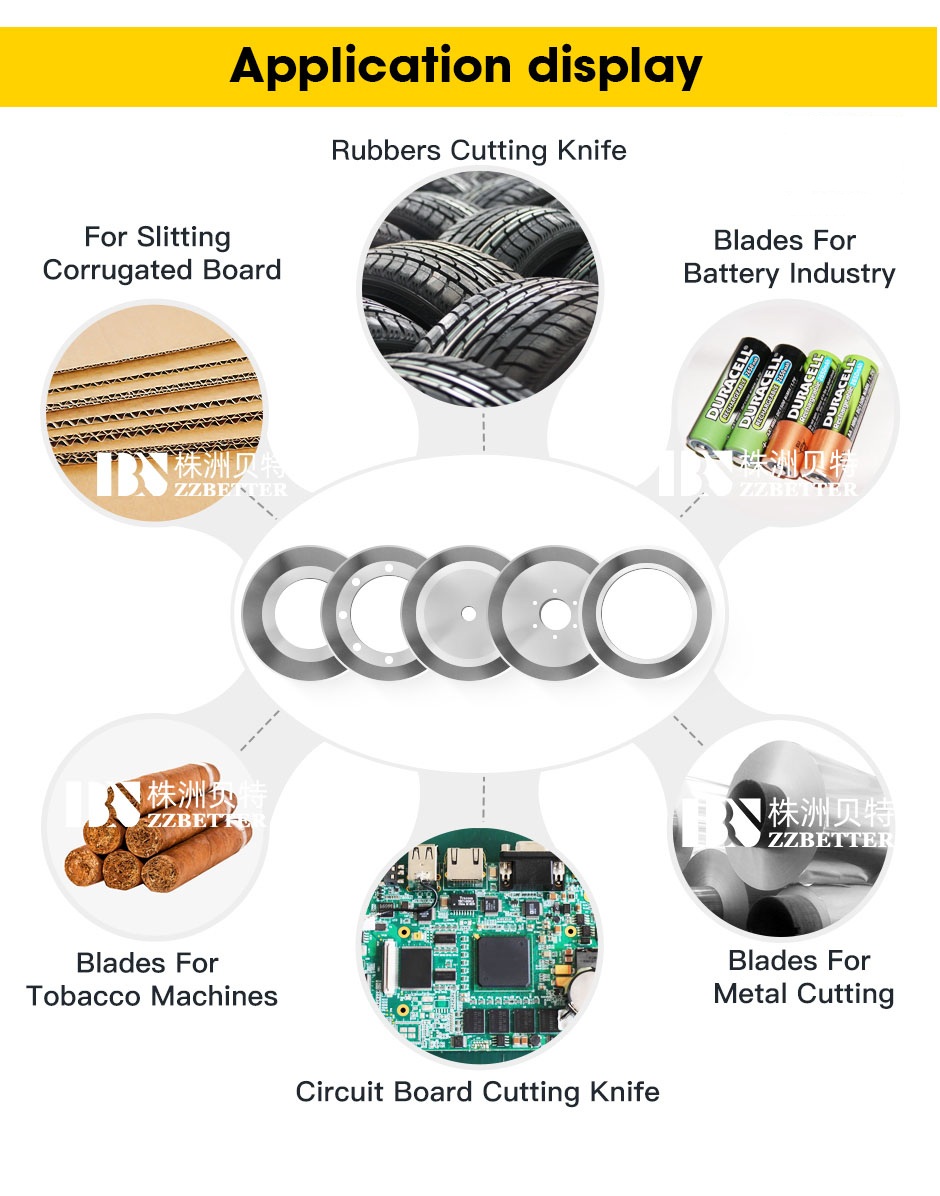

1. Application widely

Do you know what the main advantage of choosing a carbide blade over steel is? Is the toughness of tungsten carbide and its resistance to damage.

A steel blade is likely to break When cutting other hard materials, but if you use tungsten carbide blades, it will be durable enough to cut through.

Solid carbide cutting tools are a far more durable choice for strong materials. These blades are tough and capable of pushing through hard materials. So tungsten carbide blades can widely cut stone, glass, ceramic, metals, hardwoods, etc different materials.

2. Remains sharp for longer

Since a tungsten carbide circular blade is tougher than its steel counterpart, it can maintain its sharpness for longer and get dull slower than a steel knife.

That means you will not need to sharpen it frequently, which decreases additional time and effort. On the other hand, you only need to use a carbide blade sharpener on rare occasions. The tool’s capability to remain sharp is impressive. That contributes to the overall convenience of using the tool.

If you use a sharp blade, you will increase the quickness of cutting, as well as the smoothness of the cut. Decreasing the risk cause a blow-out of the grain and shattering by using dull blades.

3. High-temperature resistant

Overheating is a serious issue for steel cutters. Too much heat can cause various problems for steel blades. For starters, high temperatures might change their shape. Those deformations could render steel tools unusable.

Thermal deformations are a common issue, and one of the ways to fight it is by choosing carbide blades. These tungsten carbide blades are robust and resistant to general wear and tear, but also extreme heat. They can maintain optimally

Performance even when the temperature is at very high levels. The resistance of these carbide tools to heat will improve efficiency when cutting. You will be able to go through more applications than with steel units.

4. Finished clean and smooth

What is the primary consideration when using a blade to cut materials? First, It needs to make an accurate cut. On the other hand, how smooth and clean the workpiece surface will be. Tungsten carbide cutting blades can do those effectively very well.

Due to the durability and toughness of the tungsten carbide blade, the carbide edges can remain sharp for a considerable time. Only a sharp edge is capable of making smooth and clean cuts. Carbide blade tips will enable cutting various applications smoothly.

With these clean cuts, operating the tools will also be easier, which minimizes the risk of injury.

5. Easy to repair

Tungsten carbide cutting tools are particularly durable. Even if the carbide blades got dull that they are still easy to repair. And you just need to use a grinding wheel to sharpen a new edge.

The critical advantage of carbide welded tools compared to solid carbide is that you don’t have to buy a new tool in case of breaking. Once breakage happens, you might just remove the old carbide tips and weld a new one. It is much more convenient and cost than buying a new blade.

Conclusion

Tungsten carbide blades come with multiple benefits that make the cutting process easier and more accurate. What’s more, the tungsten carbide cutting blade's work life is very long. Additionally, these carbide tools can save time, effort, money, and other resources.

If you are interested in tungsten carbide blades and want more information and details, you can CONTACT US by phone or mail at the left, or SEND US MAIL at the bottom of the page.