End Mill Flutes

End Mill Flutes

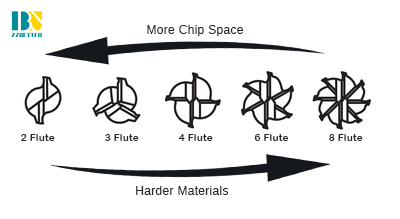

These are multiple tungsten carbide mills, excluding their shapes, the largest difference is the flute. You may wonder which part is the flute. The answer is the spiral channels on an end mill. And the design of the flute also will determine which materials you can cut. The most common options are 2, 3, or 4 flutes. Generally, fewer flutes mean better chip evacuation, but at the expense of surface finish. More flutes give you a nicer surface finish, but worse chip removal.

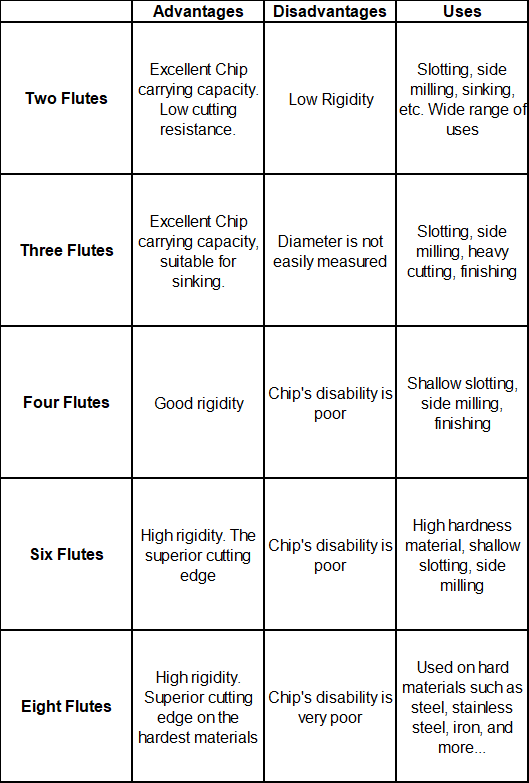

Here are a chart to show the disadvantages, advantages, and uses of different tungsten carbide end mill numbers of flutes.

After comparing the chart, we can find that end mills with fewer flutes on the cutting edge will provide better chip clearance, while end mills with more flutes will be able to a finer finish and operate with less vibration while being used on harder cutting materials.

Two and three flute end mills have better stock removal than multiple flute end mills but a significantly decreased finish. End mills with five or more flutes are ideal for finishing cuts and cuts in harder materials but must operate at lower material removal rates due to their poor chip evacuation properties.

If you are interested in tungsten carbide end mills and want more information and details, you can CONTACT US by phone or mail at the left, or SEND US MAIL at the bottom of the page.