How to Test Tungsten Carbide Rotary Burr?

How to Test Tungsten Carbide Rotary Burr?

Tungsten carbide rotary burr is used for forming and cutting. It is widely used in various materials, including cast iron, steel, cobalt, titanium, aluminum, gold, nickel, glass fiber, copper, plastic, wood, bronze, jade, platinum, and zinc. They are also used to remove sharp edges. People use these carbide rotary burrs for different drilling tasks. It is important to get high-quality burrs to perform tasks correctly.

Cemented carbide rotary burr factories usually need to test these burrs before selling them. Every burr has to go through various tests, including grinding test, cutting test, and sharp edge test. If it passes all tests effectively, it is sent to the distribution part.

1. The grinding test

When carbide burs are finished, factory workers will take them out for grinding tests. At first, they will use these burrs to grind hard materials. If they perform well in this part, they will be taken to grind softer materials. If they grind soft material effectively, they will be taken to the next test, cutting test.

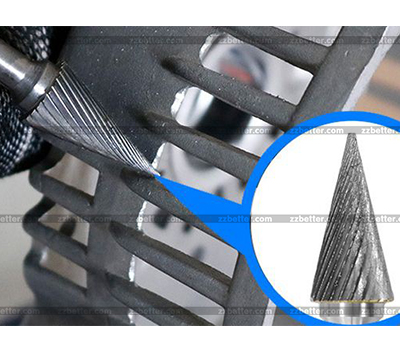

2. The cutting test

Different from the grinding test, the cutting test is to cut materials. Workers mark lines on the materials to cut them. If the burrs can cut them, they can be used in cutting.

3. The sharp edge test

This part is about the sharp edge test. Tungsten carbide rotary burrs are also used to remove sharp edges of different materials, like wood, steel, cobalt, titanium, gold, and so on. These materials should remove these sharp edges and smooth the surface of this material. If burrs passed all these three tests, they are excellent. Finally, it will send it into the market for distribution worldwide.

Our carbide burrs manufactured are machine ground from a specific grade of carbide. With all these good performances of tungsten carbide, carbide burrs can be used on much more demanding jobs than high-speed steel. Thus tungsten carbide is always a better choice for long-term performance.

For more information, please visit: www.zzbetter.com