Production Process and Forming Process of Cemented Carbide Rod

Production Process and Forming Process of Cemented carbide rod

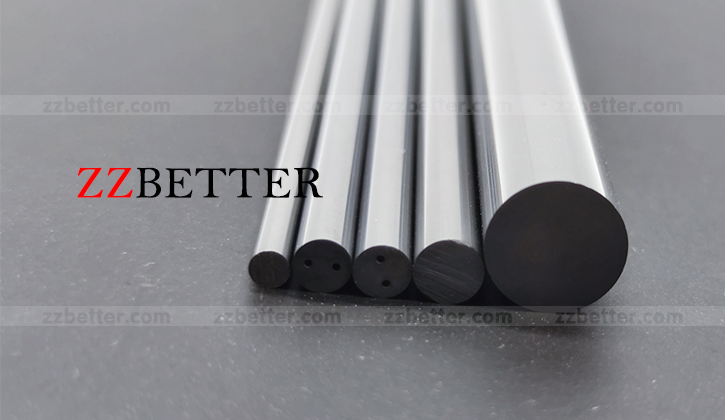

Cemented carbide bars are cemented carbide round rods. Cemented carbide is a composite material composed of a refractory metal compound (hard phase) and a bonding metal (bonding phase) produced by powder metallurgy.

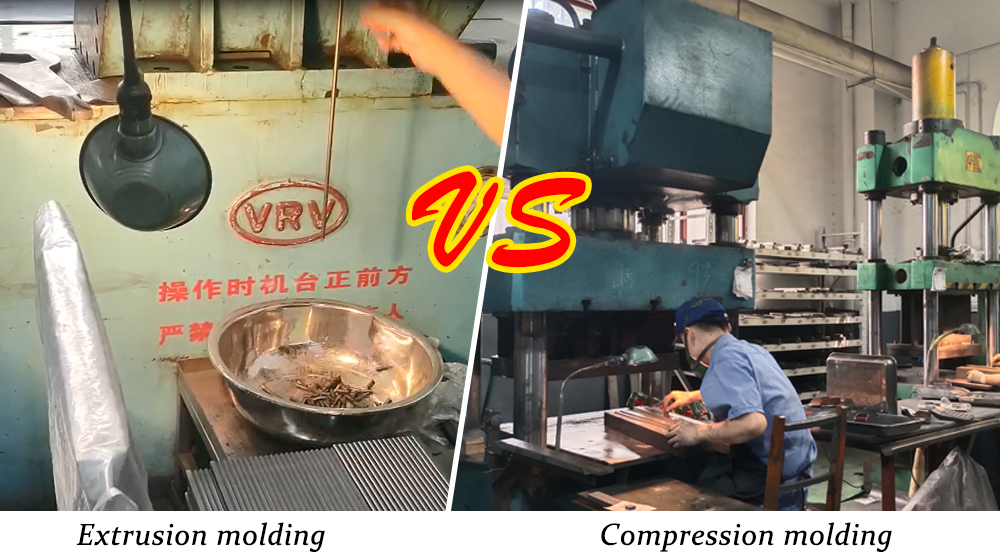

There are two forming methods for cemented carbide round rods. One method is extrusion forming, which is a suitable way to produce long round rods. This kind of cemented carbide rods can be cut to any length the user wants during the extrusion process. However, the overall length cannot exceed 350mm. The other is compression molding, which is a suitable method for short bar production. As the name implies, the cemented carbide powder is pressed into a mold.

Alloy material is made of refractory metal and a bonding metal through a powder metallurgy process. Cemented carbide has a series of excellent properties such as high hardness, wear resistance, good strength and toughness, heat resistance, and corrosion resistance. especially its high hardness and wear resistance, which remains unchanged even at a temperature of 500 °C, and still has a high hardness at 1000 °C. Carbide is widely used as tool material, such as turning tools, milling cutters, planers, drills, boring tools, etc. for cutting cast iron, non-ferrous metals, plastics, chemical fibers, graphite, glass, stone, and ordinary steel, and can also be used for cutting Wet grinding of difficult-to-process materials such as heat-resistant steel, stainless steel, high manganese steel, tool steel (ball mill, drying cabinet, Z-type mixer, granulator)---pressing (with side-pressure hydraulic press or extruder)-- - Sintering (degreasing furnace, integrated furnace or HIP low-pressure furnace)

The raw materials are wet-milled, dried, mixed with glue after proportioning, then dried and stress-relieved after being molded or extruded, and the final alloy blank is formed by degreasing and sintering.

The disadvantage of round bar extrusion production is that the production cycle is long. Extrusion of small-diameter round bars below 3mm, cutting off both ends will waste a certain amount of material. The longer the length of the small-diameter round bar of cemented carbide, the worse the straightness of the blank. Of course, the problems of straightness and roundness can be improved by cylindrical grinding in the later stage.

The other is compression molding, which is used to produce short bars. As the name implies, there is a mold that presses the cemented carbide powder. The advantage of this cemented carbide bar forming method: it can be formed at one time and reduce waste. Simplify the wire cutting process and save the dry material cycle of the extrusion method. The above shortened time can save 7-10 days for customers.

Strictly speaking, isostatic pressing also belongs to molding. Isostatic pressing is the most ideal forming method for producing large and long carbide round bars. Through the sealing of the upper and lower pistons, the pressure pump injects the liquid medium between the high-pressure cylinder and the pressurized rubber, and the pressure is transmitted through the pressurized rubber to make the cemented carbide powder press-molded.

If you are interested in tungsten carbide products and want more information and details, you can CONTACT US by phone or mail at the left, or SEND US MAIL at the bottom of the page.