Why Do Our Carbide Rods Get Praise from Our Customers?

Why Do Our carbide rods Get Praise from Our Customers?

1. Powder Excellent.

We use the 100% virgin material powder for carbide rods for all our standard grades for carbide rod manufacturing.

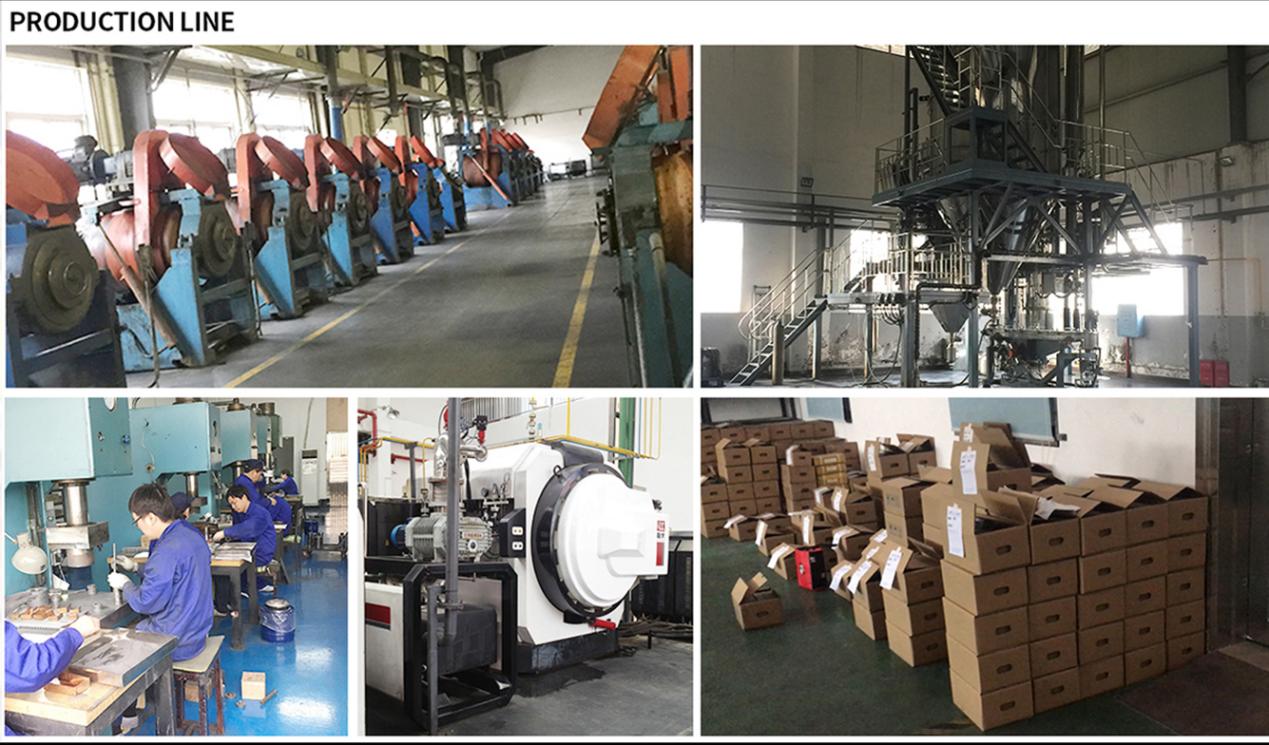

2. Advanced production equipment

Spray tower

The spray drying tower is mainly used to dry the cemented carbide mixture, and because it is in the form of a spray, the alloy particles are more uniform.

HIP Sintering

The advanced computer-controlled HIP furnaces from Germany are applied to provide more pressure during the sintering process in order to get a denser structure.

Hardness test of tungsten carbide

The cemented carbide is a metal that can reflect the difference in mechanical properties in chemical components, tissue structures, and heat-treatment processes. Therefore, the hardness test is widely used in the inspection of carbide properties, which can supervise the correctness of the heat treatment process and the research of new materials. The hardness detection of tungsten carbide mainly uses a Vickers hardness tester to test HRA hardness values. The test has a strong shape and dimensional adaptability of the test piece with high efficiency.

3. Fast Production

Three different compaction methods, including extrusion, automatic press, and cold isostatic press, are used for the maximum efficiency of carbide rod manufacturing.

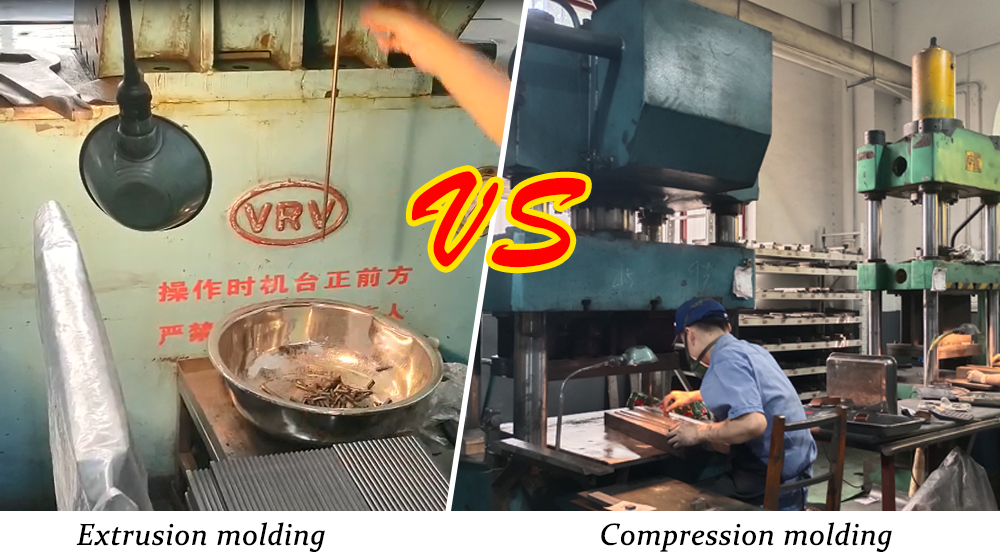

Extrusion

Extrusion is the most popular method of producing carbide rods. It is a very practical way to manufacture long carbide rods like 330mm, 310mm and 500mm, etc. However, its time-consuming drying process is the weakness that we have to pay attention to.

Automatic Press

Automatic pressing is the most effective way to press short sizes like 6*50,10*75,16*100, etc. It can save cost from cutting carbide rods and it doesn’t need time to dry. So the lead time is faster than extrusion. However, long rods cannot be manufactured by this method.

Dry-bag isostatic pressing

Dry-bag isostatic pressing is the latest technology for making carbide rods. It can produce long bars like 400mm and doesn’t require wax as a forming agent. What's more, it doesn’t need time to dry. This is the best option when making big diameters more than 16mm.

4. Professional team

Our company gathered professional staff members in the area of designing, producing, and marketing. Our workers are well trained and experienced. Our team is honest, positive, credible, and glad to provide solutions for customers and create value.

Zzbetter has got GB/T19001-2016 / ISO9001:2015 certificate, with advanced equipment, test facilities, and professional employees. We strictly carry on ISO9001:2015 requirement to guarantee the quality.

If you are interested in tungsten carbide rods and want more information and details, you can CONTACT US by phone or mail at the left, or SEND US MAIL at the bottom of the page.