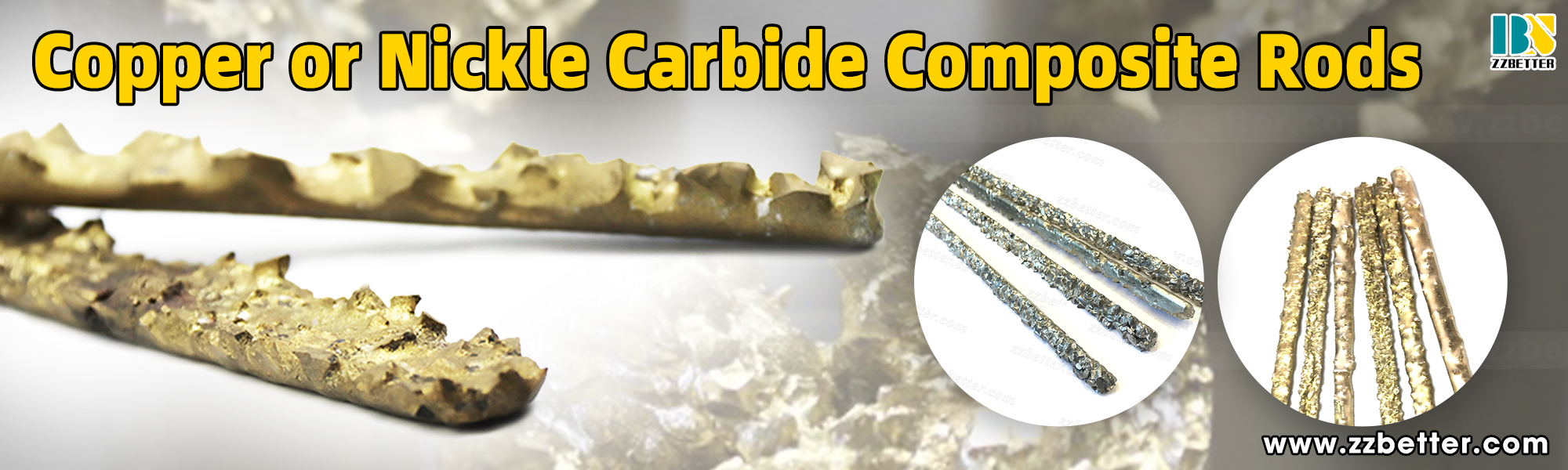

Copper or Nickle Carbide Composite Rods

Copper or Nickle Carbide Composite Rods?

Carbide Composite Rods are made of cemented carbide crushed grits and Ni/Ag(Cu)alloy. The cemented carbide crushed carbide grits with high hardness have excellent wear resistance and cutting ability.

The hardness is about HRA 89-91. Another composition is Ni and copper alloy, of which strength can be up to 690MPa, hardness HB≥160.

It is mainly used for surfacing welding the oil, mining, coal mining, geology, construction, and other industries in some serious wear and tear or artifacts of both cuttings. Such as milling shoes, grinding, centralizer, reamer, drill pipe joints, hydraulic cutter, scraper, plow planer knives, core bit, piling drill, twist drill, etc.

There are two different components of composite rods. One is copper carbide composite rods, and the other is Nickle carbide composite rods.

What is the same between Copper composite welding rods and Nickle Carbide Composite Rods?

1. Their main composition is crushed sintered tungsten carbide grits.

2. They both have high hardness and good performance in cutting or wear.

3. The appearance is the same. They both look like gold.

4. The application method is the same.

What is the difference between Copper composite welding rods and Nickle Carbide Composite Rods?

1. Composition is different

Copper carbide composite rods, the material of them is Cu and carbide grits. Crushed sintered Tungsten Carbide grains bonded with a bronze nickel matrix (Cu 50 Zn 40 Ni 10) with a low melting point ( 870°C ).

The main material of nickel carbide composite rods is cemented carbide grits too. The difference is that most of the crushed carbide grits are Nickle base tungsten carbide scrap.

2. Physical performance is different

Both types of composite rods are used for hard facing and wear resistance protection.

Due to the different compositions, their physical performance is different.

For the nickel carbide welding rods, without or little cobalt element, and instead with the Nickle, it will make the composite rods without magnetic. If the tools or wear parts require non-magnetic, you can choose the Nickle composite rods.

If you are interested in our rods and want more information and details, you can CONTACT US by phone or mail at the left, or SEND US MAIL at the bottom of the page.