End Mill Shapes and Problems Troubleshooting

End Mill Shapes and Problems Troubleshooting

There are many kinds of tungsten carbide end mills designed with a variety of different factors to enable you to choose the right end mill to match the material you’re working on, and the type of project you’re going to use for. Each end mill tip shape is designed for a particular purpose. Some common cutter shapes are ball nose, square, corner radius, and Chamfer. The characteristics of each end mills are as below:

Ball nose Mills produce a rounded pass and are ideal for 3D contour work Feeds and Speeds

A radius end mill is most recommended because they ensure constant smooth cutting and chip removal. Radius edges increase corner edge strength and produce the desired radius and meet functional print requirements.

A Chamfer end mill will create a cutting action that assists in breaking chips in most materials. Chamfering allows for heavier feed rates and more efficient production. Their angled profile allows chamfer, bevel, and other angled cuts in materials such as aluminum, brass, bronze, iron, and steel.

Square end mills Commonly referred to as Flat End Mills, they are used for general milling applications including slotting, profiling, plunge cutting, and milling square shoulders. Square End Mills produce a sharp edge at the bottom of the slots and pockets of the workpiece. Flutes on each of the end mills' cutting heads carry chips away from the workpiece to prevent damage to the end mill or workpiece. Square end mills are used on CNC or manual milling machines.

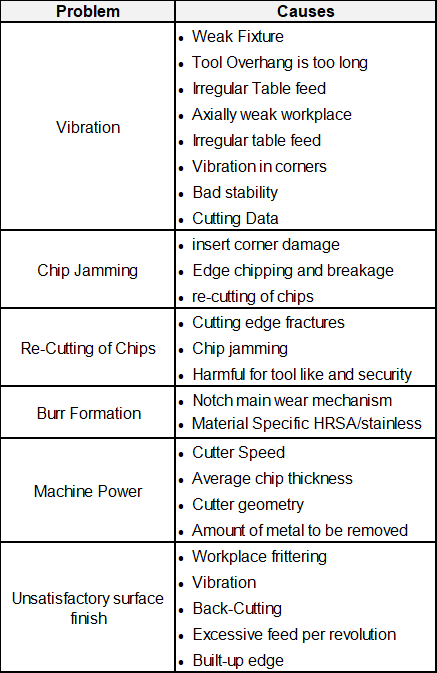

Here are also some troubleshooting about the problems you might meet when you use the end mill:

If you are interested in tungsten carbide products and want more information and details, you can CONTACT US by phone or mail at the left, or SEND US MAIL at the bottom of the page.