Three Ways You Are Hurting Your End Mill

Three Ways You Are Hurting Your End Mill

End Mill is one kind of milling cutter to do the process of removing metal by CNC Milling machines. There are various diameters, flutes, lengths, and shapes to choose from. Users choose them according to the material of the workpiece and the surface finish required for the workpiece. Do you know how to use it properly when using it? Here are some tips to prolong the lifetime of your end mills.

1. When using the end mill, running it too fast or too slow will shorten its life.

Determining the right speeds and feeds for your tool and operation can be a complicated process, but understanding the ideal speed (RPM) is necessary before you start running your machine to ensure proper tool life. Running a tool too fast can cause suboptimal chip size or even catastrophic tool failure. Conversely, a low RPM can result in deflection, bad finish, or simply decreased metal removal rates. If you are unsure what the ideal RPM for your job is, contact the tool manufacturer.

2. Feeding it too much or too little.

Another critical aspect of speeds and feeds, the best feed rate for a job varies considerably by tool type and workpiece material. If you run your tool with too slow of a feed rate, you run the risk of recutting chips and accelerating tool wear. If you run your tool with too fast of a feed rate, you can cause tool fracture. This is especially true with miniature tooling.

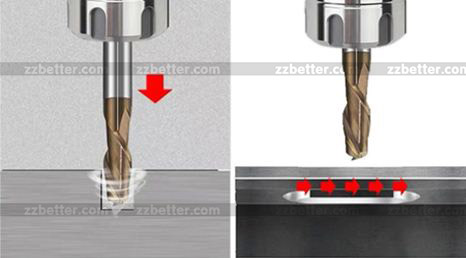

3. Using improper tool holding and its effect on tool life.

Proper running parameters have less of an impact in suboptimal tool holding situations. A poor machine-to-tool connection can cause tool runout, pullout, and scrapped parts. Generally speaking, the more points of contact a tool holder has with the tool’s shank, the more secure the connection.

The three tips above are the things you need to pay attention to. If you are interested in tungsten carbide products and want more information and details, you can CONTACT US by phone or mail at the left, or SEND US MAIL at the bottom of the page.