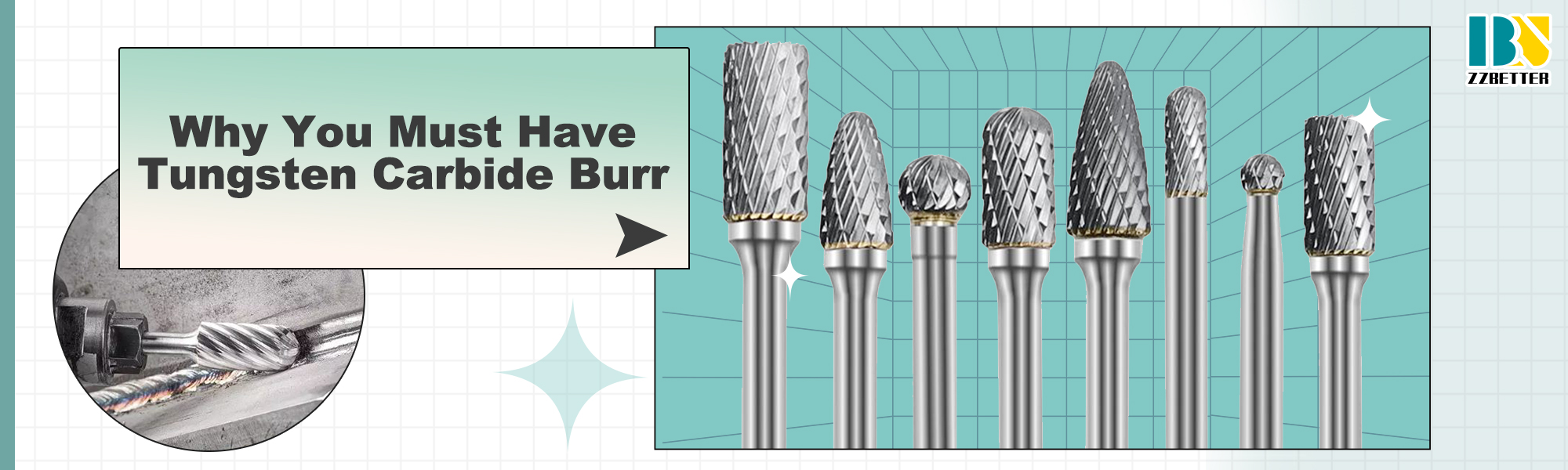

Why You Must Have Tungsten Carbide Burr

Why You Must Have Tungsten Carbide Burr

The tungsten carbide rotary burr can be used to process cast iron, cast steel, carbon steel, alloy steel, stainless steel, hardened steel, copper, and aluminum. Since the carbide rotary burr is hand-controlled on a high-speed rotation, the pressure and feed speed are determined by the service life and cutting effect of the tool.

Advantages

1. It can process iron, cast steel, carbon steel, alloy steel, stainless steel, copper, aluminum, etc, and non-metals such as marble, jade, and bone. processing hardness can reach HRA ≥ 85.

2. Basically, it can replace a small grinding wheel and no dust pollution.

3. High production efficiency. The processing efficiency is more than ten times higher than the handmade file and is nearly ten times that of the small grinding wheel with the handle.

4. Good processing quality and high finish. It can be processed in various high-precision shape mold cavities.

5. Long service life. Durable is ten times higher than that of high-speed steel tools, which is more than 200 times higher than small grinding wheels.

6. Tungsten carbide burrs are easy to use, safe and reliable.

7. Comprehensive processing costs can be decreased by several times.

Applications

1. Finishing various metal mold cavities such as shoe molds, etc.

2. Various metals and non-metallic process engraving, craft gift engraving.

3. Clean up the feed, burrs, and weld of the casting, forging, and welding in machine casting factories, shipyards, automotive plants, etc.

4. Chamfered rounds and trench processing, cleanup pipelines, finishing pipelines, mechanical plants, repair shops, etc.

5. Decoration of the impeller flow path in the automobile engine factory.

![]()

Summary

With high hardness, excellent wear resistance & corrosion resistance, tungsten carbide rotary burr has a high performance in the high-tech manufacturing field which has a strict requirement of quality, stability, and reliability.

If you are interested in tungsten carbide products and want more information and details, you can CONTACT US by phone or mail at the left, or SEND US MAIL at the bottom of the page.