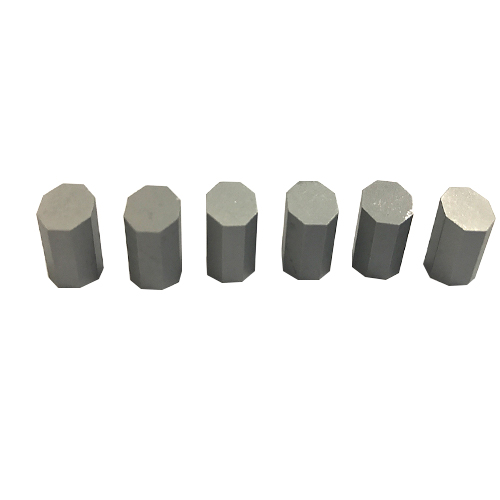

Tungsten Carbide Buttons

Tungsten carbide buttons, also known as cemented carbide buttons, or carbide mining inserts, have many different types, including carbide parabolic buttons, carbide ball buttons, carbide spoon buttons, carbide coal cutter buttons, carbide road tips for digging roads, carbide flat head buttons, carbide wedge buttons, and carbide conical buttons. Tungsten carbide buttons can be used for rock drilling, oil mining, coal mining, snow removal, civil construction, and so on.

Tungsten carbide studs, also called cemented carbide studs, carbide buttons, and carbide studs for HPGR. The tungsten carbide HPGR STUDS which is made from tungsten carbide will inlaid on the body of the high-pressure grinding roller. Tungsten carbide studs roller has a service life of more than 6 times longer than that of the surfacing roller surface.

With a rich experience of more than 10 years, ZZBETTER is now a professional tungsten carbide buttons manufacturer to provide you with various sizes and shapes of products.

Tungsten Carbide Button:

Common grades for tungsten carbide buttons

Grade | Density g/cm3 | TRS MPa | Hardeness HRA | Applications |

YG4C | 15.10 | 1800 | 90.0 | It is mainly used as an impact drill for cutting soft, medium and hard materials |

YG6 | 14.95 | 1900 | 90.5 | Used as electronic coal bit, coal pick, petroleum cone bit and scraper ball tooth bit. |

YG8 | 14.80 | 2200 | 89.5 | Used as core drill, electric coal bit, coal pick, petroleum cone bit and scraper ball tooth bit. |

YG8C | 14.80 | 2400 | 88.5 | It is mainly used as the ball tooth of small and medium-sized impact bit and as the bearing bush of rotary exploration drill. |

YG11C | 14.40 | 2700 | 86.5 | Most of them are used in impact bits and ball teeth used to cut high hardness materials in cone bits. |

YG13C | 14.2 | 2850 | 86.5 | It is mainly used for cutting ball teeth of medium and high hardness materials in rotary impact drill. |

YG15C | 14.0 | 3000 | 85.5 | It is a cutting tool for oil cone drill and medium soft and medium hard rock drilling. |

Tungsten carbide studs:

Grade Information of carbide HPGR studs:

The grades below are exclusive grades we developed for HPGR. Good wear resistance and high strength are suitable for metal smashing with high working efficiency.

ZZBT Grade | Density (g/cm3) | Hardness (HRA) | T.R.S (MPα) | Recommended Application |

UBT92 | 14.65 | 88.2 | 2560 | For grinding soft and middle hard stones or mines |

UBT89 | 14.35 | 87.0 | 2850 | For grinding soft and middle hard stones or mines |

UBT85 | 14.20 | 85.5 | 2500 | For grinding hard stones or mines |

TAGS: Carbide Button Manufacturer Mining Button Insert Manufacturer Carbide Button Factory

Mining Button Insert Factory Carbide Button Supplier Mining Button Insert Supplier

Carbide Studs Carbide Stud HPGR Carbide Stud Carbide Studs for HPGR HPGR Studs Pins

Carbide Buttons Manufacturer

With modern tungsten carbide production lines, advanced spray drying technology diversified forming processes, and automated HIP sintering equipment, ZZbetter provides over 500 tons of tungsten carbide products for customers at home and abroad every year. Facing the complex and ever-changing needs of the industry, we always strive to offer comprehensive and high-precision processing solutions to satisfy our customers.

Zhuzhou Better Tungsten Carbide Co., Ltd

ADDRESS:Huanghe North Road, Tianyuan District, Zhuzhou City, Hunan Province, China. 412000

Phone:+86 18173392980

Tel:0086-731-28705418

Fax:0086-731-22286227 28510897

Email:zzbt@zzbetter.com

Whatsapp/Wechat:+86 18173392980